The lid of the Polaris PWK 1766CWr kettle has stopped opening. The button is pressed, but the latch does not open. A short article - a review of the kettle and how to disassemble its lid.

Looking ahead, I will say that the copy that came to me turned out to have a hidden manufacturing defect. Therefore, when returning under warranty, it makes sense to give it back with a note, “I ask you to carry out the examination in my presence,” so that a careless examination does not write that the breakdown is your fault (fell, crushed the button, etc.).

Polaris PWK 1766CWr

We open the jammed lid by inserting a thin awl, knitting needle or steel wire into the gap next to the spout. Then, from bottom to top, draw over the spout, at the location of the latch, and press the latch. You can try using a bent paperclip.

We begin disassembling the POLARIS PWK by removing the plug.

Polaris disassembly

It is soft and if you pick at it, for example with an awl, a mark will remain, traces of disassembly will be visible. Unscrew the screw under the plug. Unscrew the two screws under the cover.

We take the handle away. There is a tin at the bottom of the lid. We just hook it from the side, it’s better to start closer to the handle. The latches on which it is held will straighten and it will be removed.

Disassembling the kettle lid

After this, a broken element spilled out - a lever transmitting pressure from the button to the latch.

Broken teapot element

As stated above, this is a manufacturing defect. If you look at the scrap, it was clear on both sides that the plastic inside was not solid. There were bubbles of considerable size. You could try to glue it, but to work on the kettle, I simply removed the latch from the lid and removed the spring at the place where the lid is attached to the handle that holds the lid open. As a result, the steam does not lift the lid, the kettle boils and turns off normally. In order to securely put the tin in place or get to the latch mechanism, the lid must be completely disassembled. To remove the top tin, its clamps are bent from the inside and it is squeezed out in the same way as the bottom one. The lid consists of 2 plastic parts. First, the 2 outer latches at the base of the handle are released. Then the internal ones, along the perimeter of the lid. The plastic inside is soft, there was no fear of breaking them. Then the lower and upper tins are put on, the lid halves are snapped into place, and the latches near the handle are snapped into place.

Polaris cover assembly

The promised review of the PWK 1766CWr kettle was working properly before this trouble, no complaints. Pros: I liked the assembly. Everything is fixed well and does not wobble. Availability of constant heating mode. Wires at bends, near connections, are protected with additional thick insulation, and not just a thin shrink tube. Cons: The lid stopped opening. Like most kettles, the water level is inserted into the body on two silicone gaskets. Sooner or later, teapots with levels begin to leak. Heating - I saw a burnt kettle and part of the room with it, which was left on heating.

How to cut polycarbonate

You can cut monolithic polycarbonate with either an electric jigsaw or metal scissors. Moreover, the latter option is less noisy and dusty.

The recesses are made with a regular round needle file.

After that, the edges are trimmed with sandpaper.

We try on the future glass in place. It should fit tightly enough.

After this, carefully heat the insert on gas.

Here I was in a hurry, and, as a result, made a mistake (I slightly overheated the edges where the bubbles appeared). To avoid repeating a similar mistake, it is better to hold the part higher. It will take a little more time, but “boiling” will not occur.

After warming up, quickly put the insert in place and, pressing it along the contour with a glove, make a bulge.

All that remains is to assemble the “sandwich” in reverse order and the lid for the kettle is ready.

Operating rules

Filling your kettle with water is very easy.

It is important to follow the basic rules, violation of which leads to device failure and accidents.

The kettle only fills when the power is turned off or removed from the base. Each device must have minimum and maximum water level marks. If there are none, the water must cover the heater. Underfilling leads to burnout of the heater, and overfilling leads to premature shutdown and water splashing out of the spout.

How to fix the lid of a Philips kettle? (Option No. 2)

If you still need an original plastic insert for a kettle, then for a while you can get out of the situation as follows.

Let's disassemble the cover. Take a baking sleeve. Fortunately, it is intended for food products and high temperatures.

Place the lids between the two parts and assemble in reverse order. We make holes with self-tapping screws during assembly. We cut off the excess with scissors or a stationery knife. Be careful not to damage the rubber seal.

Recommended articles:

Checking with a multimeter

Most people who repair equipment have such devices. To do this, you need to turn on the multimeter (tester) in resistance measurement mode, and then touch the contact rod with one end of the measuring device. If the thread inside the heating tube is broken, an incorrect value will appear on the tester screen. The operating resistance for a kettle with a power of 2000 W will be 25 Ohms. If no deviations are found inside the tube, then one of the taps needs to touch the contact rod, and the other to the metal tube. If there is no short circuit, then the screen will show an infinite resistance value. And if it is, then it will be fixed and such a heating element cannot be repaired.

Kettle lid (do-it-yourself repair): 4 comments

Thanks for the idea. I cut it from a thin lid from a plastic food jar, it bends and does not need to be heated

Thank you. I somehow didn’t think about this option.

Thank you! Made it from foil in 5 minutes. - completely satisfied!

Electrical equipment today is in every home, because it allows a person to live in full conditions and save time. Such installations include electric kettles. They heat up water in a matter of minutes. But during operation, a variety of breakdowns occur.

Not everyone is ready to take such a device to a specialist, because it also needs to be found. But how to fix an electric kettle with your own hands? This is not a difficult process if a person knows how to hold a screwdriver. Before you start repairs, you need to understand what the main reasons are, as well as what breakdowns occur.

Please note that all equipment should always be handled carefully - this will increase its service life. It is better to purchase high-quality products from well-known manufacturers.

Repair of electric kettles in China

Products from Guangdong Province are widely known. China is rich in economic and other interesting zones that provide tax and some other benefits to manufacturers. The United States is not enthusiastic about the conflict with the heirs of communism, whose fate Nietzsche predicted a couple of centuries ago. Today we will look at how to repair a Chinese electric kettle, made according to a standard design for a company that does not seek to reveal the true origin, with a 95% probability of being a representative of Eastern Europe, perhaps, the Russian Federation. Let's see what our compatriots indulge in - the best examples of the world's household appliances pass through the hands of Guangdong workers.

China's GDP ranks second. Japan is third. Not bad, considering the state of the Land of the Rising Sun, which survived World War II. Feudal Japan became the world's largest electronics manufacturer.

Types of breakdowns

Damages may be the following:

- Leaks.

- The device does not turn on.

- The lid is broken.

These are the main problems with which people come to the workshop. But you can restore the integrity of the entire unit with your own hands. To do this, you should take into account any available instructions and begin work. If you have no experience, you cannot skip more than one point, because we are talking about an electric unit. Statistics show that more than half of all people throw away a broken kettle, but you can always try to restore the device.

Conclusion on electric kettle repair

As readers understand, this is one of the cheap models of Chinese teapots, made to order from a certain company. The maintainability of the product is zero. Difficult to disassemble, even more difficult to assemble. By picking, it is easy to spoil the presentation and functionality. The bottom got dressed quite simply, with considerable effort and threatening clicks. The lid caused a lot of trouble. Skillful use of a hairdryer will help. With only a screwdriver, disassembly will be difficult.

We recommend evaluating the assembly in the store. How difficult will it be to disassemble the device in order to repair the electric kettle with your own hands? If the product is disposable, this is not very encouraging, and if, in addition, it is dangerous... no comment.

We hope that after such a detailed review, readers will be able to repair Tefal electric kettles and repair Scarlet electric kettles. After all, most products are made in China. We want to say goodbye, look at the pictures, evaluate, study. If the bimetallic strip is inserted the wrong way, the electric kettle will stop turning off when it boils! Although the click is heard.

Principle of operation

To understand how to repair an electric kettle, you need to know its operating system. To heat the water, a special electrical device is built into the bottom. Depending on the manufacturer, its shape varies. For fastening, special bushings and metal screws are used, which are firmly fixed to a waterproof seal.

The shape of such protective elements is varied. This could be a washer, gasket, bushing. When this element breaks its seal, water begins to leak. To fix such a breakdown, you simply need to replace this component. They are sold in the store. To avoid mistakes, you will have to take the kettle with you or remove this element.

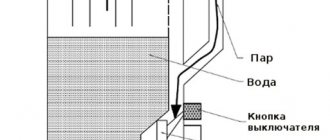

Before you repair an electric kettle, it is worth understanding the principle of operation. When water heats up, steam is formed - this is a natural process. It, in turn, exits through specially formed outlets. And in this process, the operating principle of the entire unit is important. Because if it approaches the biometric plate, then the toggle switch is automatically activated. The device turns off.

What's on the kettle:

- Indicator and button block. Thanks to this addition, you can know what the current water temperature is and create suitable working conditions.

- Unique water level sensor. It shows the level and is capable of transmitting data to the application.

- Two heaters. They are necessary for spot heating and full heating.

These are the features that every kettle has. Although today manufacturers, trying to occupy a larger part of the market, are coming up with other possibilities to make the operation of the unit more convenient. In addition, there is always a protective element. Its main task is to turn off the kettle when the water boils. It also triggers if, by mistake, the element was started without liquid. Thus, the manufacturer tries to protect users from accidents (for example, from fire of the device).

Statistics show that it is empty kettles that often end up being switched on. It was accidents that prompted manufacturers to create such additional conditions for the operation of the entire device. Therefore, modern kettles are considered to be completely safe.

Troubleshooting

Before delving into the technical jungle of electrical circuits, it would obviously be useful to check the obvious nuances: the correct location of the structure on the receiver, connecting the device to the network and the power connector. If these points are excluded, then you can start disassembling the case.

Important! All work must be carried out with the equipment completely de-energized.

Disassembling the electric kettle

As for disassembling the case, the manual should contain detailed instructions for this part. For example, the sections “Replacing the thermostat”, “Heating element” and others include a local diagram of these elements and the places where the parts are fixed to the body. More expensive models of kettles require trouble-free disassembly (screws, rivets, etc.), while parts of budget devices are often glued together. Let's consider an approximate algorithm of actions when disassembling an electric kettle.

For example, we took an ordinary budget device, which does not differ in design from more expensive models - electric kettle Vitek, Tefal, Polaris, Scarlett and others. By the way, in this model, as in the Vitek VT-7009(TR), the container is made of heat-resistant glass. So, let's analyze the unit using the following algorithm.

- Remove the device from the stand (base) and unscrew all the screws located on its bottom panel.

- After this, it is necessary to pry off the plastic cover located on the handle with special care using a thin screwdriver. This should be done carefully because in different device models the latches may be located in different places and can be easily broken.

- After removing the cover, you can see the mounting screws. They also need to be removed.

- After unscrewing all the fasteners, using a little force, disconnect the handle with the cover from the body.

- Next, disconnect the housing from the bottom of the unit.

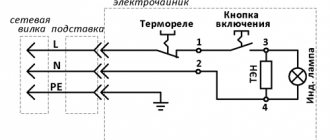

- At the bottom of the case you will see all the main elements of the device: contact group, thermal relay and heating element.

- Pay attention to the bimetallic strip (on the right in the picture). If damage is visible on it or it has a worn-out appearance, then this may be the reason why the electrical appliance has stopped turning off. The plate is not repaired, but replaced with a new one.

But how to disassemble the kettle if, when you unscrew all the screws on the bottom, it does not come off? Those who disassembled such a device encountered difficulties, which often ended in the breakdown of the device. Since the process is quite difficult to describe, it is better to watch a video on this topic.

Ringing elements

To diagnose faults you will need a multimeter. The test itself consists of sequentially ringing the circuits from the power plug to the heating element. It is not difficult to eliminate the problem with the outlet; just connect any other household appliance to it.

- Switch the measuring device to voltmeter mode and insert the probes into the socket. If the voltage is normal, then move on to the next elements.

- We check the plug, cord and contact group on the electric kettle with a multimeter: set the ringing mode and press one probe to the pin of the plug, and with the other we check the two conductive wires and grounding. All this is on the receiver. If the ringing is positive, then the stand is working, and the problem needs to be looked for elsewhere.

- We disassemble the bottom of the kettle to get to the terminal block. As a rule, it is fixed with a special paste and combined with a thermostat. Using a multimeter, we call all contacts: each should react on its outer or inner ring. If there is no signal, then we disassemble the block and clean the contacts using sandpaper or technical rags. After cleaning from carbon deposits and oxidation, we collect the elements and call them again. If there is no signal, we replace the wires with new ones and repeat the diagnostic procedure.

- Next, let's check the button. You can get to it in several ways: disassemble the handle or pull out the button itself if it is latched. We turn on the multimeter and touch the core that goes to the heating element with one probe, and the cable on the switch with the other. In the disabled state there will be no signal, whereas when the button is activated it should ring. If not, then we repair or replace the switch with a new one.

Checking the electric kettle with a multimeter

The heating element is checked last. To make a ringing call, you need to check the contacts going from the heating element to the base and the switch wires. If there is a signal, then the heating element is ok. You also need to make sure that the heating element does not touch the housing and does not short out. To do this, apply the probe to one terminal of the heating element, and touch the tank with the other. A positive signal indicates a breakdown in the housing.

Checking the thermostat

Devices of this format are a little more complicated than ordinary kettles due to the presence of a thermostat. The latter allows you to maintain the desired temperature in the tank without involving the user. Depending on the specific model, the thermostat may be located either on the handle or on the receiver. The base includes five contacts where a pair is added for the thermostat.

The ground loop wires must match those of the power cable. To check each core, you need to touch the pin in the plug with one probe, and check the contacts of the base connector with the other. Those terminals that relate to the thermostat ring at a resistance of 100 kOhm. If the multimeter indicates infinity or too low numbers (twice or more), then the thermostat circuit is damaged.

If everything is in order with the element, then further diagnostics are performed according to the principle described above. That is, we check the block, the heating element and the button. But before the procedure, you need to disconnect the thermostat.

To correctly assess the condition of the heating element, first of all you should find out the resistance of the heating element. We divide watts (W) by the network voltage (V) and get the current (A). The power is indicated in the specification for the device, and the number of volts in a regular outlet is standard - 220. Now we divide the voltage (V) by amperes (A) and compare the resulting resistance (Ohm) with the actual one.

What needs to be checked before repair?

Before repairing an electric kettle, it is worth checking the obvious things:

- The plug must be inserted into the socket and the corresponding start button must be pressed. Often the problem concerns the plug and socket. Sometimes the connector moves from side to side. It turns out that there is no power supply from electricity.

- Incorrect fixation. This happens sometimes, but rarely. It is better to exclude this from the rules.

When these reasons have been verified, but the unit has not started working, it is worth continuing work. If an electric kettle breaks, how to fix it? To avoid creating a more complex breakdown, you need to follow simple steps.

Comments (1):

Oh, here the heating element goes almost along the entire perimeter, mine was 2000 watts, by the way, it only didn’t reach half the circumference. That kettle broke, but the heating element did not burn out, but the contacts turned black. They used to be gold plated, but now they are made from shit. By the way, the size of the heating element directly affects the noise level when heating water. If I were creating my own kettle, I would definitely make a heater with as much area as possible, or a long spiral, by the way, I also like spiral ones better. And you don’t need too much power. Now I have a 1000-watt kettle, it works without problems, the contacts don’t burn, the plastic doesn’t crack.

What actions should be taken?

It is important to disassemble the unit, but without making mistakes and remembering the entire procedure. What you have to do:

- The base of the kettle is removed - this is the lid.

- After this, you need to remove all fasteners. They are on the handle of the kettle. It is necessary to unscrew it carefully so that the thread remains in the same form. They often get damaged, so sometimes you have to buy new ones.

- The handle is carefully removed from the kettle. Sometimes you have to make an effort. But it is important not to break the installation itself.

- Before repairing the Tiffany electric kettle, you need to remove the rocker arm. It is made of the same material as the unit itself. This is an important component of the entire structure.

- Next you need to go over the entire surface and remove any plastic components that interfere with disassembly.

- The kettle switch is removed.

- Next, you need to visually evaluate the biometric plate so that there is no damage to it. If something is detected, then this is the reason why the kettle is not working. If there are no defects, you will have to continue troubleshooting.

Once you have disassembled the entire installation and have not found the problem, you need to continue searching.

How to disassemble the body of an electric kettle with a closed heating element

Regardless of the model, the design of electric kettles is almost the same, so disassembly always begins with removing the lid. To remove it, you need to find two self-tapping screws; they can be positioned differently:

- in older models, the screws are at the top. That is, immediately after lifting the lid, access will open to them;

- In modern devices, you must first remove the top part of the cover. It is secured by two grooves that fit into the base of the handle. They just need to be moved apart a little. Then you will have access to the screws that need to be unscrewed.

On some models, the top cover can be removed along with the handle. Therefore, before you begin to remove it, you need to study the design and do not make any effort when removing it.

Removing the lid of the kettle

Then we move on to the lower part of the body. You need to turn the electric kettle over and find three self-tapping screws; in some models there may be more, but they are in plain sight, so this should not be a problem.

Unwinding the electric kettle

However, detaching the bottom will require a little patience and effort as there are teeth around the perimeter that fit into the housing hole. They need to be carefully snapped off. This must be done in stages so as not to break them and damage the case. Most often, they snap off quickly with a slight pressure from the screwdriver. But if the device has been in use for a long time, the procedure may take a little longer, since the body may simply stick to the base.

After removing the base, a heating element will appear in front of you if it is a disk kettle in which there is no direct contact between the heating element and water. If the cause of the breakdown is most likely the heating element, then you can ring it already at this stage of disassembly. This is done with a special device. With its help, you can find out if there is a break in the spiral inside the heating tube, or if something has happened to the contacts. If during the test the tester shows a value equal to infinity, then the heating element needs to be replaced. If the value is between approximately 50 and 200 Ohms, everything is fine with the heating element.

Checking the heating element for functionality

Checking the thermostat or thermostat. To do this, unscrew the screw located at the bottom of the handle. Then carefully remove it. Some modern models of electric kettles may have a single handle and top cover design, so you need to do all manipulations carefully.

Removing the handle of the electric kettle

Then we find a self-tapping screw inside the handle. It is located directly under the button to turn the kettle on or off. It needs to be unscrewed and then removed. To do this you will need a Phillips screwdriver. After removing it, you need to ring the thermostat - all connection points. To disassemble the thermostat itself, you will need to remove the switch cover; they are easily removed. Then we check this element. If there is such an element, it is better to replace it. If not, let's look further. The cover is removed by pressing and sliding it forward. After which you can clean all contacts.

What should you pay attention to?

Sometimes the kettle starts to work slowly and the water heats up ineffectively. The difference may occur over time, but why is this observed? The fact is that scale accumulates on the heating element, and its performance is reduced several times. If an electric kettle breaks, how to fix it? The problem can be solved using special cleaning products. They are sold in stores. After purchase, you should refer to the instructions, because they are different for each device model.

The fact is that everyone creates anti-scale products according to their own principle. The application process will depend on the composition inside. Therefore, when answering the question of how to fix a broken electric kettle, you should not exclude such a situation as the formation of plaque. Some people try to clean it with a sharp object, but this solution will not bring the desired result and can damage the heating coil.

Another unexpected thing that is not a breakdown is the open lid. If it is not tightly fixed, the kettle will not turn on. The work does not start because the steam that comes through the hole may be blocked. This happens rarely, but it does happen. And the hole becomes clogged with a coating of lime. The steam has no way to the biometric plate and nothing happens.

Suspected problems and repair methods

During operation, the kettle may break down. This is not necessarily due to improper use or maintenance. The elements of an electrical appliance are subject to wear and tear, so they need to be replaced or repaired. If the electric kettle does not function, solve the problem yourself by finding the source of the breakdown.

Not functioning

It’s unpleasant if the kettle is plugged in in the morning, but the appliance doesn’t work. The reasons may be:

- Damage to the power cord and plug. It is necessary to make a ring of elements - one probe touches the plug contacts, the second touches the connector on the base of the device. No signal indicates an interruption. The cable must be replaced.

- Intermittent contact at base. With prolonged use of the device, the contacts may burn out. They should be cleaned with fine-grain sandpaper. If necessary, they are replaced.

- Damage inside the switch. The condition is checked by disassembling the handle.

When sediment forms on the two connections, the electric kettle does not turn on, because the circuit does not close when turned on. How to fix: carbon deposits are cleaned with sandpaper or a thin file. Before repairing, the device is checked with a multimeter to determine the break.

Takes a long time to warm up

Due to the high performance of the device, boiling water in an electric kettle usually takes a few minutes. If the device heats up slowly, there is a problem with the heating element.

Despite the proper filters, lime builds up on the electric coil over time, which prevents the water from boiling quickly. The scale is removed so that the spiral does not burn. How to do it:

- Fill the kettle with water.

- Add 1-2 packs of lemon.

- Boil water and leave for 30 minutes.

- Pour out the liquid and rinse the device several times.

Lemongrass works well against scale. Cleaning is repeated 2-3 times. If the thickness of hard deposits of hardness salts on the heater is too large, purchase a special cleaning agent.

Doesn't turn off

Sometimes it happens that an electrical appliance heats water, but does not turn off. This problem is dangerous, because if you forget about the kettle working, the water boils away and the tubular electric heater burns out. Main reasons:

- The most common problem is a lid that does not close tightly. This prevents the required volume of steam from occurring inside the device.

- The steam outlet is clogged. It is located under the lid of the device for boiling drinking water, at the junction of the body and the handle. The steam outlet should be cleaned with a toothpick.

- Damage to the contactors of the plate made of bimetal, which regulates the shutdown of the mechanical device for transmitting a signal when water boils. When diagnosing, remove the body cover of the electrical appliance and handles.

The plate is located under the terminal box and at the start. The switch contacts should disconnect when exposed to platinum and turn off the device. If the contactors are burnt out or connected to each other, you need to fix the problem by cleaning them.

When the elements are beyond repair, the switch is replaced and the electric kettle is assembled. The thermostat is located in the housing at the bottom; to replace it, the device must be completely disassembled. Repair the button of an electrical appliance as follows:

- De-energize the device and remove it from the stand.

- Loosen the screws on the bottom plate (bottom).

- Pry off the handle using a screwdriver.

- Remove the mounting screws and remove the handle.

- The device body is carefully removed.

- The approach to the system connecting the contacts of electrical wires, the switching device, and the heating element is open.

The bimetallic plate is replaced with a new element if it is worn out. Determine the appearance of the thermostat (handles), inspect the contactors, clean them of carbon deposits. If this does not help, the handle is replaced.

Doesn't boil

If the kettle turns off before the water boils, a possible reason is solid deposits of hardness salts formed on the heater. The heating element is equipped with a safety element against overheating. As a result, it is not the water that is heated, but the coil. When the fuse blows, the electric kettle turns off, but the water does not boil. To resolve the problem, you need to clean it.

- Water with lemon added – 2 packs. 20 g each

- Soda - 3-4 tablespoons per 1 liter.

- Vinegar - 4 tbsp. spoons per 1 liter.

- Special descaling agent.

Subsequently, the flask is freed from solid deposits. Boil water 2-3 times until the sediment disappears, and use the electrical appliance as usual.

Another reason why equipment turns off before boiling is a weakened heating element or a broken thermostat.

Leak

Sometimes the electric kettle leaks. To fix it you need to find this place:

- The bottom panel of the kettle and the top guard attached to the latches must be removed. Wash the device, seal and tubular electric heater. If the seal is severely worn, it is replaced. The disassembled components are dried and collected. Then pour water and leave on a dry towel for 15-20 minutes. If there is no leakage, the electrical appliance can be used.

- Leakage through the open heater mounting point. Due to a weak connection between the tank and the heating element, water may leak out. It is necessary to tighten the fasteners that hold the heater - remove the cover on the body and handle, tighten the spiral screws. Afterwards, the electric kettle is filled with water and the leaks are checked. If tensioning the heater fastening elements does not solve the problem, the equipment must be disassembled to replace the rubber gasket in accordance with the same principle described above.

- Leakage at the glass mounting point with water level indicated on the body. Plexiglas is susceptible to microcracks or water leakage at the point where the silicone gasket is installed. The rubber seals are replaced and the glass is sealed.

Nuances

How to fix an electric kettle if it doesn't turn on? This is not uncommon, and it is worth understanding why this occurs. It also happens that the switch simply fails. The reason is ambiguous - this happens because the signal to the biometric plate is blocked. The simplest reason is that the pusher is locked in the wrong position. But the plate itself breaks down due to damage.

But is it possible to repair an electric kettle with such a breakdown? Here everything is more complicated, and not everyone can cope with the task. It should be noted that when the switch fails, only a professional can help. You will need to not only perform all actions correctly, but also have the necessary spare parts.

The actions of a professional may be as follows: he will have to change the element. The procedure itself is not complicated, but you need to find where the switch itself is located. How to fix the switch of an electric kettle? Most often this toggle switch is located on the handle. If this is so, it will be easy to deal with, but if not, then it will not be so easy. The difficulty is that the kettle has many different fasteners.

In addition to the bolts, there are some parts that will also have to be removed and then reinstalled. To prevent the procedure from being delayed, you will have to remove the handle and cover of the unit itself. These steps will help answer many questions and make the recovery procedure simple.

Housing, side panel when repairing an electric kettle

Below are photos that allow you to personally enjoy the views of a detail of the simplest design. There will be links to the pictures in the text. If you want, look, if you don’t want, scroll blindly. Disassembly begins with the lid. If you skip this step, you cannot remove the side panel that hides the LED plus switch. With the side panel on it is more difficult to remove the bottom. Dilemma. Do the opposite, if you are looking for difficulties, then you don’t have to remove the lid at all!

Lid. It is held in place by two lugs and two pins. It’s a plastic monolith, you’ll be tortured to disassemble it, installation is even more difficult. The first photo shows the pins perfectly. There are two screws on the sides, immediately unscrew and remove the side panel. Everything is neat inside - plus models, we often find a whole mess of wires. Let's move on to the bottom.

There are three screws around the connector where the grounding terminal is provided (the structure hangs in the air). We unscrew it and make sure that the bottom is slow to come off. Along the perimeter there are six plastic teeth that fit into six holes in the housing. So that it does not accidentally fall apart, worn out by use, there is a guide on the sides of each tooth. One by one, you will have to snap off the teeth separately with a screwdriver (see photo below), if you break them, you will break the bottom when removing them. We took a picture of each tooth, illustrating what was said. We put the dismantled parts aside and look at the switch.

How to fix the problem?

There are statistics by which experts can tell what problems arise most often. If the electric kettle does not turn on, how to fix it? Since it is the switch that is constantly in operation, it fails for many people. Do you really have to go to the master? Not at all. The recovery procedure itself has several stages.

It is important to inspect the part. If it is cracked, then without replacing it it will not be possible to return the unit to operation. Finding such parts is not always easy, because many people simply get rid of such a kettle and do not repair it. This means there is not much demand for parts.

Sometimes the button just gets stuck. There is a special spring here. It stretches, and after that it will be difficult to work with starting the unit. When analyzed, it will become clear what the main reason is. Replacing it is not that difficult. But when something is done incorrectly, even after assembly the situation does not return to normal.

We disassemble an old model electric kettle

The disassembly steps are slightly different:

- unscrew the screws that are located at the bottom of the device;

- the lower side part of the device is removed;

- then access to the heating element, switch and thermostat opens.

In older models, to get to the main components of the device, you do not need to unscrew the entire structure, just unscrew a few screws. However, if the power and shift button is located at the top of the handle, then complete disassembly is inevitable.

We disassemble an old-style electric kettle

To check the functionality of the heating element in kettles where the heating element is open, it is enough to remove one cover, and then it is released.

However, the cause of a breakdown may not always be related directly to the device itself. Its stand may fail. Therefore, it is important to know how to disassemble the kettle stand to check its functionality.

How to fix the lid of an electric kettle?

Sometimes it simply stops closing, which is why the device does not turn on. We need to figure out why this happens. It happens that scale accumulates on the rim, and it becomes a barrier between the lid and the kettle. In this situation, you will have to wash it using special means. The principle of action of such substances is the same. Required:

- Pour into a kettle, pour water.

- Boil.

- Drain.

If nothing has changed, you will have to repeat the procedure. As all the experts say, it is better to prevent this than to restore it afterwards. Preventive cleaning procedures will not be superfluous and can extend the service life of the electrical device. There is no big difference in how to repair a Vitek electric kettle or any other. Also, the instruction manual always contains a lot of useful information. The manufacturer tries to talk about weak points and suggest how to solve some problems in the work.

Please note that when using special chemicals for descaling, you should remember safety precautions. Such products are very aggressive, so work is performed with rubber gloves. In addition, the kettle itself must be thoroughly rinsed with running water. The inner surface must be completely rid of any remnants of this chemical.

How to replace the heating element in an electric kettle

To replace the heating element in an electric kettle, you need to completely disassemble it:

- remove the cover. To do this you will need a Phillips screwdriver. Raise the cover and unscrew all the screws;

- remove the handle - you need to unscrew the screws at the bottom of the kettle, then unclip the handle. Depending on the model, the mechanism may be located at the bottom of the device or directly on the handle itself;

- to dismantle the heating element, you need to remove the on/off button of the device, then unscrew the screws that were hidden under the handle;

- After this, the heating element can be freely removed. Then install a new heating element and put all the parts back together.

After completing the repair, do not forget to check the functionality of the device. Replacing the heating element is a quick and easy process that anyone can handle. When repairing an electric kettle, you must follow safety precautions, especially when checking the device.

Presence of leaks

This is another problem that many people face. The kettle is used frequently, so water leaks are inevitable. But how to understand this problem? First it is important to understand why this happens:

- One of the common reasons is a violation of the sealing of the plastic case. Another reason is the failure of the water indicator. You need to give it a visual assessment. Often small cracks are simply visible. It is from them that water begins to ooze.

- Another reason is when the heating element loses its original rigidity. If an electric kettle leaks, how to fix it? Everyone can solve this problem themselves by simply tightening the existing fasteners.

- Sometimes leaks occur due to wear of the seal. How to fix an electric kettle if it is leaking? In this situation, even tightening all the fasteners will not help remove the damage. In this case, you cannot heat the water, otherwise a short circuit may occur. The leaks will stop when the seal is replaced. This is the only solution that is relevant in the fight against this breakdown.

- The worst damage is the formation of holes in the bottom of the kettle. Not everyone is ready to understand that their kettle is seriously out of order. This happens for various reasons, but they all boil down to one thing - careless handling of the device. In such a situation, you definitely won’t be able to solve the problem yourself. There is no point in taking the device to a service center, since few technicians will restore such a device. Of course, if the kettle is expensive, then you can spend money on repairing it. But this is the case when it is better to buy a new one.

There are many reasons why an electrical appliance fails. Before you panic, you should eliminate basic operating errors.

Switch, temperature sensor: the point of view of an electric kettle repairman

The photo shows from the bottom position. A shiny circle with a cut is a mechanical sensor. Thanks to the bimetallic plate, seizing the moment, the electric kettle turns off. The water boils and an increased amount of steam begins to be released. There is a small hole in the housing located under the switch, covered with a circular loose plastic plug (see photo). The plate is installed, located above the gate pair. Boiling begins and the temperature rises sharply. After a moment, you can hear a click. The tongue of the plate, made up of a pair of metals, bends sharply upward. Looks like a bimetallic relay.

Now the switch. Not so simple. The part has no visible connections, except for the metal bracket shown in the photo on the side. The upper movable part is attached to it. When we turn on the kettle, the tip of the switch rests on the tongue of the round plate with a cutout, and the bracket is compressed. Thanks to the design, the parts retain their initial position indefinitely. Click! The slightest tug releases the bracket, returning the switch to its original position.

Let's examine the bottom of the body. Here are:

- circular connector;

- rolled spiral;

- LED divider resistor rated 14 kOhm.

While the switch is dormant, the LED glows blue. Full voltage of 230 volts is applied. The photo clearly shows: the resistor was burnt, the contacts were inserted into the clamp terminals, one did not withstand inspection. I had to solder it. The divider resistor is connected in parallel with the rolled heater. The electric kettle turns on - the glow changes to orange. Dual LED (school teachers left out?), unlike typical use, both shades work simultaneously while the water is boiling. The addition of electromagnetic waves of different shades produces orange. It is difficult to list the shades that form the superposition (the repairman is deeply indifferent).

Remove the resistor, or it will burn out - nothing bad will happen. The LED will simply stop changing hue, tracking changes in the position of the switch. Color is not related to water temperature. It is easy to notice that there is no thermal fuse. We believe there is simply no protection. Those who wish can equip the part with a metal case, next to the ring connector. Provide protection against empty switching. This kettle may cause a fire if not protected. We recommend adding a thermal fuse to the device. Place it not somewhere in the center, but around the perimeter of the heating element, increasing reliability.

The resistance of the heating element is 30 Ohms. The photo shows through fractions the power values on a metal surface of 220 and 240 V. Enough to understand what can break. The design of the electric kettle is simple, even a kettle can be repaired, but... It was easy to remove the lid and put it back! We hope that readers will solve the question on their own; we find it difficult to answer. But we will show you how to disassemble the switch for those who want to clean the contacts. The gap distance is tiny, steam is in the air. Just look at the two screws from the photo: they are covered with rust, although the electric kettle has not been properly used.

We believe that six months later you will need to refresh your contacts. Let's look at the switch:

- Place your finger on the plastic ear that secures the switch to the body.

- Use your thumb to press the button on the opposite side.

- Squeeze your fingers gently and the retaining bracket will fly out. Protect it more than the apple of your eye, otherwise the electric kettle will only have to be thrown away.

Assembly is carried out in reverse order. Hook the bracket with the front part of the button, press it against the base, and carefully place the part in place without any extra effort. The bimetallic plate can be easily removed with a knife or screwdriver. Self-repair of electric kettles consists of such little things, otherwise it won’t take long to break the lid while putting it on! The contacts are made of bronze, visible in the photo. You cannot clean it with alcohol or gasoline, there is plastic nearby. We think we'll have to get hold of acetic acid; the switch is waiting in line.

You will have to disconnect the terminals. The Saturn model in question is not a simple one. The photo shows a small hole in the terminal to which the spike of the second half corresponds. If you press there with an awl, the connection can be disassembled without any problems. Otherwise... It’s impossible to separate one from the other. The process is aggravated: the joints are protected by heat-shrinkable cambric, which is poorly heated with a hairdryer. It crumbles easily, barely holds on, but... does not come off. Therefore, if necessary, cut and disassemble the assembly. The clamp terminals are disposable. The resistor wire jumped out, it was not possible to crimp it back, it was not convenient. I had to solder it.

Weld plastic with a soldering iron. Along the way, using the necessary additives (polyethylene). Choose a material that is compatible with the food industry. Use heat-resistant glue that is harmless to humans.

Summing up

An electric kettle can be repaired in half of all cases. Each device has its own operating principles, and if they are violated, breakdown cannot be avoided. But if something happens (water leaks, the button sticks, does not turn off on its own), you should not continue to use the device. This can lead to short circuits, fire and other problems.

When starting a repair, you need to be prepared for any situation, which means preparing the necessary tools (screwdriver, soldering iron, knife, electrical tape). During the repair process, you should not make sudden movements, because the teapots are plastic and therefore fragile. When disassembling them, it is worth remembering the sequence of work, otherwise it will be difficult to assemble them again.

Bosch Private Collection kettle ☕️ How it works ⚒ Disassembly for spare parts

Bosch TWK 6007N electric kettle, made in PRC (= made in China), which was severely degraded over 3 years of operation and began to leak from below

From the very beginning, a design problem was discovered: the lid does not lock in the open position and tends to tilt back at 45 degrees, which was very annoying when pouring water. In addition to the build-up of sediment on the outside of the kettle in all places that have even the slightest hint of a gap,

The plastic of the case began to crumble into dust. The dirt on the outside of the kettle is absorbed into the plastic and cannot be washed off. Inside too:

scale and sediment from the metal disk of the heater can still be chipped off (or dissolved with acid), but at the top of the body the scale seems to have been absorbed into the plastic and cannot be washed off in any way. But most importantly, the kettle began to leak intensively from below. Let's reveal the villain:

We unscrew the bottom and discover a terrible picture: the entire bottom from the inside is covered in scale build-up, i.e. the kettle has been leaking for a long time, only the water did not flow out of the bottom, but rotted there and evaporated gradually. Based on the traces of scale at the top between the heater disk and the housing, we understand where the leak came from:

The leakage is observed exactly from the half of the heating element that is adjacent to the handle. That is, we have a conclusion: such a design of a kettle, with a handle that is not attached from below (see Photo 1, Photo 2), leads to the fact that when we tilt a heavy hot kettle filled with water, the back wall under the handle pulls the body away from the heating element disk (as if making the body elliptical, while the heating disk is round).

Squeeze the heating element disk down (by hand, through the neck of the body). We see that between the heating element and the body there is only a silicone (gray) gasket:

And this gasket could shrink over time. Or, as it expanded due to heating, water flowed under it, leaving a sediment there as it dried, worsening the sealing.

And guess what? All kettles with a disk flat bottom heater have exactly the same gasket: “iron” ones (with a steel body), glass ones, and ceramic ones. In earlier times, heating elements were like this:

This spiral was attached to the body through a reliable flat gasket made of something dense. This is a heating element from a Tefal kettle from the 90s, which served for 10 years, never leaked, and was replaced only when its plastic body crumbled into dust, right down to through holes.

Well, after 3 years only horns and legs remained of this modern “high-tech” Bosch:

I must say that the teapot was made of very high quality in detail. For example, all these parts in Photo 11 are spare parts of strategic value: they were plowed for 3 years under the daily influence of steam and even henna - not the slightest rust, i.e. these screws, screws and springs are most likely made of stainless steel in bulk (and not just coated with nickel/zinc/oxide film). And the filter mesh on the front of the kettle (the big thing with a gray frame in Photo 11) has a stainless steel mesh, completely intact.

Descaling

If the kettle turns off without boiling water or takes a long time to heat up, it should be thoroughly cleaned inside to remove deposits.

To prevent it from accumulating in large quantities, the kettle is periodically washed with a proprietary product. In this case, you should make sure that it does not damage the plastic housing. Scale impairs heat transfer from the heater to the water. In this case, the spiral overheats and quickly fails.

Important! When purchasing anti-scale products, you should read the instructions for their use.

Common descaling technology:

- the kettle is filled halfway with water, which should be boiled;

- the plug is removed from the socket and the recommended descaling agent is added to the water;

- after the formation of bubbles stops, the water is drained and new water is poured in;

- The water is boiled, then drained and the kettle is thoroughly rinsed.

If a lot of deposits have accumulated, the cleaning procedure is repeated.

The mesh filter is removed and cleaned of scale and other contaminants. If deposits are not removed, they are soaked in an anti-scale solution for several hours, after which the filter is washed with water.

Checking the heating element of the kettle indiscriminately

Indeed, using a multimeter you can check an electric kettle without disassembling it. It is enough just to check the outgoing contacts (they go to the base).

The multimeter should show some resistance - 150-170 Ohms often. If the device shows infinity on the screen, the heating element is burnt out and requires replacement. However, this is not possible in every electric kettle design.

Dismantle the heating element only if you have found a similar one for replacement. But very often the heating element is intact (absolutely working). The reason for the malfunction is hidden in the control contact. It is he who turns off the electric kettle when the water in it boils.

Due to the passage of high amplitude current through it, it becomes charred. Simply clean the contact with a nail file and the kettle will work again.

The video clearly demonstrates the process of repairing an electric kettle:

one of the solid-iron chrome-plated outside Chinese automatic teapots with backlight died here, a TEN horseshoe heater made of an incomprehensible alloy of roofing felts with zinc or with aluminum SOLDERED TO THE BOTTOM OF THE KETTLE OUTSIDE - there is a recess in the bottom, a tinned copper plate is soldered to it and to it a TEN TEN similar I have a dead one, along with the bottom from a plastic kettle, I want to re-solder, but the 200W solder broke off, even at 260V from LATR the solder does not melt (it is similar to the one with which the central contacts of Soviet light bulbs were soldered) WHO KNOWS WHAT SOLDER IS THERE, WHAT TO REPLACE, WHICH FLUX is better (borax will work??) and most importantly, WHAT TO MELT IT, WHAT POWER AND TEMPERATURE IS NEEDED. Yes, there is still a problem: a plastic transparent plug is inserted into the bottom (fused?) or a transparent plastic plug is glued into it, there are 2 LED backlights, this rubbish can probably melt?? It’s unclear how the Chinese collect them. PS DO NOT suggest throwing it out, I will ALWAYS have time to do that.

Yes-ah-ah. Well, if you need it, there are also irons, electric burners and gas for bottom heating. if there is solder, not welding.

PS: it’s good to soak condoms in fairy before washing, and darn socks with floss. suddenly it will come in handy.

trash

:

PS DO NOT suggest throwing it out, I will ALWAYS have time to do that.

Then take it to the master who will do everything

trash

:

200W soldering even at 260V from LATR does not melt the solder.

Have you tried mixing low-melting solder?

Don't torture your ass. The crab keeps hinting and hinting at you, but you don’t intervene. The heating element is WELDED. If you really want to make this teapot, then break out the heating element by biting it, and put another one in its place. You will no longer achieve the required density of contact between the heating element and the bottom of the kettle and, accordingly, the heating area. Conclusion: 1. Is it a shame to throw it away? 2. Send a complaint to Chinland.

If it were plastic, I wouldn’t even think about taking it apart - it would ring and if it broke, I’d throw it away, but it’s a pity that it’s shiny chrome. I'll try the gas, it won't work, I'll throw it away. There’s nothing to lose, and at the same time I’ll find out if it’s welded or soldered with REFRACTORY SOLDER.

try a gas welder (small ones that run on lighter gas). first remove the plastic lamp. If it starts to melt, then remove the solder centimeter by centimeter; if not, then alas, welding.

If space allows, try using screws and a bracket to screw a new heating element on top of the burnt one.

trash

:

brilliant pathetic.

Well, the raven is also drawn to shiny things.

trash

:

brilliant pathetic.

Then tell us how many cubic meters of gas you burned. Is there a counter?

Recently I threw away the chrome plated Bork.

Selector

:

Conclusion: 1. Is it a pity to throw it away?

2. Send a complaint to Chinland. - I’ll also tell you a way - I went to the ASC to see guys I knew - they offered - I took 5 pieces of stainless steel teapots for 2 bucks each from the pre-trade, almost from complaints with a diagnosis of “leakage in the level sensor”. business for 10 minutes, and the heating element, kettle sole - for pennies. and the relatives are happy. and so that “soar your brains with this approach. well, fuck it.

trash

:

I find out it’s welded or soldered with REFRACTORY SOLDER

- will you drink from it YOURSELF after the repair?

Radio Forum is a site dedicated to discussing electronics, computers and related topics.

An electric kettle has become an indispensable appliance in any kitchen. It heats water quickly and consumes little electricity. However, like any other device, sooner or later it may fail. There are many reasons for this situation, but most often they come down to the fact that the device does not work due to damage to the heating element. Therefore, many are interested in the question of how to ring the heating element in a kettle and, if necessary, change it?