Checking the inclination of the entire plane of the laser level relative to the horizon

For those who have just started using a laser level or are just planning to purchase one, we recommend that you familiarize yourself with the general errors found in laser levels.

We install the laser level exactly in the middle between two walls located approximately 5 meters from each other. Turn on the laser level and mark the point indicated by the laser cross on the wall. We rotate the laser plane builder 180 degrees and mark a point on the opposite wall, placing the point at the intersection of the vertical and horizontal planes.

Next, we move the laser level to one of the walls and install it at a distance of 0.6 - 0.7 meters from the wall, and make the same marks on the walls by analogy as described above.

We measure the distance between points a1 and a2, also between currents b 1 and b 2. We subtract the resulting distance from the other (a1 and a2) - (b1 and b2) and compare the resulting value with the stated accuracy, if the resulting value does not exceed the stated accuracy in the instructions, This means your laser level shows the horizontal plane correctly.

Example: When checking the accuracy of a laser plane plotter, the distance between the points was: (a1 and a2) = 4 mm, and (b1 and b2) = 6 mm. Thus, the resulting error of the laser level is: (b1 and b2) – (a1 and a2) = 6 – 4 = 2 mm. We compare the resulting error with the error declared by the manufacturer.

This applies to laser levels that do not have a 360 degree horizon.

To check the horizontal plane of levels with cone prisms, such as Hilda 3D, or levels with cylindrical prisms, but also having a horizon of 360 degrees, such as ADA 6D Servoliner, the easiest way is to pass all sides of the horizontal plane through a point at a distance of 5 - 10 meters. Here you should also remember how the error is calculated correctly.

How to set up a laser level

A laser level is an accurate and easy-to-use device, but its calibration and adjustment are associated with certain difficulties. To carry out the work you will need to gain access to the internal structure of the level:

- The first step is to open the housing of the device. Before doing this, it is imperative to dismantle the batteries - if you leave them in place, when removing the casing, a short circuit may occur and the thin wires inside the device will burn out.

- The screws are unscrewed from the body with smooth movements and without unnecessary effort.

- The plastic casing is carefully removed, while the additional latches are pressed out with a thin knife without applying strong pressure, so as not to break the fixing elements.

After dismantling the housing, they examine the exposed metal structure, which requires calibration and adjustment. The large front screw is responsible for adjusting the so-called angle of attack relative to the horizontal plane, and the small side screw is responsible for the vertical tilt.

Adjusting the laser level horizontally

The sequential algorithm for setting up and adjusting a laser level with your own hands looks like this:

- The level is installed at a distance of 1 m from the wall and a clearly visible mark is made on it and on the opposite surface.

- The device is moved to another wall and adjusted until the beam hits the set mark.

- The laser is again pointed at the first wall and calibrated using a screw to understand which way the projection is shifting.

The check is carried out repeatedly and new marks are applied each time until the level begins to provide accurate readings.

The adjusting screws under the level cover are also responsible for fastening the pendulum of the device

Vertical adjustment

In a similar way, the laser level is adjusted and calibrated vertically. However, the procedure is more complicated, since you have to work with a plumb line. The algorithm is as follows:

- A tight thread is suspended in a vertical plane. It should be positioned completely vertically, without deviations or bends.

- The laser level is put into operation and its beam is directed exactly along the formed line. Ideally, the latter should be illuminated with a red or green tint along its entire length - this will mean that the construction device does not need calibration.

- If the laser level goes wrong, you will need to adjust it using the same screws hidden under the housing cover. It is necessary to loosen the clamps holding the vertical emitter and, with a little effort, turn its block in the socket.

- Once the laser beam is exactly aligned with the plumb thread, the calibration is completed and the screws are tightened again. For reliability, the check is repeated and only then the level is assembled back and the housing is mounted in place.

Advice! Rotate the laser unit in the socket manually very carefully so as not to tear it out of place. After calibration is completed, it is recommended to carefully secure the emitter with fresh glue.

Instead of a plumb line, you can take a tape measure with a weight or other suitable device

Adjusting the laser level at an angle

Adjusting the inclined laser is carried out in the same way as horizontal adjustment:

- The device is installed at a short distance from the wall and marks opposite each other are made.

- The unit is rotated and checked to see how smoothly the beam lies between the marked points.

- As the adjustment progresses, the level is adjusted using the screw responsible for the tilt, and new marks are constantly set.

When using a laser device, it is necessary to take into account that calibration and adjustment may be required even for expensive professional models. First of all, levels require debugging after a fall. However, physical shock is not the only event that can affect laser accuracy. When tested, many levels show a strong error simply after intensive use or normal transportation.

It is necessary to adjust the level until the error reaches at least the values specified in the instructions

Checking the straightness of the horizontal laser level beam

We install the laser level at a distance of approximately 5 meters from the wall and mark the point at the intersection of the vertical and horizontal beam.

Without changing the location of the laser level, we turn it 2.5 meters to the right (that is, we shift the vertical line from the marked point by about 2.5 meters to the side) and look at the left tail of the horizontal beam, if the beam is relative to our point within the error, then The laser level is configured correctly.

We repeat the same action, only we turn the device to the left 2.5 meters and check the right tail. Attention: do not shift the rotation axis when checking accuracy.

Which laser level to choose: characteristics and types, which one to buy

In the practice of private construction, in the vast majority of cases, the installation of structures or finishing is carried out with strict adherence to the vertical and horizontal main lines and planes. This, firstly, is largely predetermined by the requirements for strength, stability, durability, and, by and large, the safety of the buildings or structures being erected, and secondly, strict adherence to “geometry” gives buildings, premises, and finished finishing an emphasized accuracy.

Which laser level to choose?

Until recently, the main control tools of the builder were a plumb line, a simple spirit level, a water level, a square, etc. The acquisition of a high-quality construction bubble level was considered a great success. But today the situation has changed radically - laser equipment is increasingly coming to the aid of builders, making it possible to carry out markings with the highest accuracy and carry out constant monitoring during the work. And such a tool is already becoming not only the privilege of professionals - more and more home craftsmen want to have it in their working “arsenal”. Therefore, it is quite natural for the query that is so popular in Internet search engines: “which laser level to choose.” Let's try to understand this in more detail.

Principles of design and operation of laser levels (levels)

So, a laser level is an optical electromechanical device that visually projects lines, points or planes located strictly vertically, horizontally or at a certain angle set by the user onto building structures or surfaces.

The use of such devices provides many advantages:

- Measurements and markings are carried out with high accuracy, usually not exceeding fractions of a millimeter per meter, which is hardly achievable using traditional instruments.

- Laser devices quickly prepare for work and are able to provide the necessary points, lines or projections of planes immediately onto a large construction or repair site.

- No special qualifications are required for the worker - the operation of such devices can be mastered very quickly.

- The use of laser levels allows you to do it on your own in many cases without assistants.

- The time required for marking operations is significantly reduced, up to 40÷60%.

Basic design elements of a laser level

The variety of modern models is very wide.

Models of laser levels are distinguished by a very wide variety. However, they all consist of several systems and mechanisms arranged in one body and interacting with each other. These include:

— source of light radiation;

— optical system;

— installation mechanism and self-leveling device;

— power supply;

— manual or remote control of the device;

— a housing that ensures the protection of the device from mechanical damage, moisture, and dust.

- The source of light radiation in such devices is always powerful LEDs. These semiconductor elements are capable of creating a high-density monochromatic flux of a certain wavelength, without giving off too much heat, without consuming a lot of electricity, and without fear of accidental mechanical damage.

Laser levels with red and green beams

As a rule, modern devices of this class use two types of LEDs. The first ones, with a light wavelength of 635 nm, emitting a red color (with a slight yellowish tint) are still on most laser levels. In new modifications of devices, a gradual transition to LEDs with green radiation, a wavelength of 532 nm, can be seen. This frequency is closer to the peak of light perception by the human eye, and lines “drawn” at this level are more visible, which is especially important in sunny weather when working outdoors.

Stayer laser levels prices

Stayer laser levels

True, the design of devices with a green beam is somewhat more complicated, they are more energy-intensive, and are significantly more expensive.

- An optical system is necessary to focus the beam and give it the desired direction and configuration - from a point to a scattered flat flow in a certain sector, giving a straight line on the obstacle.

The optical design is a combination of prisms and lenses. It can be stationary, motionless, or have a rotating head - this will be discussed below.

The accuracy of the laser level itself and the visibility of the points and lines it creates directly depend on the quality of the optics.

- The installation mechanism may differ for different models.

Some inexpensive devices will have to be set manually using bubble levels.

The simplest laser levels are, in fact, a familiar bubble level into which an optical system with an emitter is built-in. Such a device must be accurately installed on a tripod, and by rotating the adjusting screws, the exact horizontal position must be achieved. Only then can you start working.

Laser levels with a self-leveling system are more convenient in this regard. Before starting work, they are also installed on a tripod or on a surface (wall bracket, etc.). They usually also have adjustment screws (feet) and bubble levels. But high precision during installation is not required. If the deviation from the horizontal does not exceed the specified value (usually from 3 to 5°), then a special pendulum or gyroscopic mechanism will make the necessary corrections itself, and as a result the optical unit will take the required position.

More advanced models are equipped with a self-leveling mechanism

Moreover, even during operation, the stabilization system will monitor the correct position and compensate for possible small deviations. If the shift is too significant, exceeding the self-regulating capabilities of the device, an audible or visual signal will be given that intervention from a specialist is required to reinstall, for example, on a more stable base.

Most modern laser levels are already produced with a self-regulation system of varying degrees of complexity and accuracy.

- The laser level can be powered from regular batteries (for simple household-grade models) or from nickel-cadmium (nickel-metal hydride) batteries, which ensure operation of the device for a fairly long time - up to 10 hours or more. Naturally, in this case, the laser level kit must include an appropriate adapter for regular recharging of batteries.

- The controls for a laser level are usually simple, and consist of a panel with several buttons that enable certain functions, and indicators that indicate, for example, the status of the device or the charge level of power supplies.

Many professional-class models are equipped with remote controls. This is a very convenient option if, for example, you have to carry out work alone, especially on a large construction site.

When working on large sites, remote control becomes a useful option.

Laser levels are available with a built-in rangefinder function - “electronic roulette”. Such products have a digital display panel on which measurement values are displayed with an accuracy of several millimeters.

- Most modern laser levels are housed in a housing made of impact-resistant plastic, protected from external influences, and are usually also supplemented with damping rubber pads - to reduce the likelihood of damage to the device due to accidental impacts during construction or repair conditions.

Types of laser levels

All devices of this class can be divided into three groups:

- Point laser priors are static axis builders.

- Static line builders.

- Rotary plane builders.

Static axis builders

Such devices belong to the category of the simplest. The lens system provides an output of a similar level of thin direct rays that are projected onto surfaces into points.

Marking a horizontal line with a dot level

The absence of complex prismatic optics ensures maximum light intensity, and usually devices of this type have a long range.

Number of beams may vary

The number of rays created may vary. In simple devices, which are often called laser plummets, there are three of them - directed forward, strictly horizontally, and two vertical, down and up, at the zenith and nadir. It is very convenient when marking, for example, frame structures for interior partitions, when it is necessary to achieve a perfect match between the lines on the ceiling and the floor.

More advanced models may also have rays directed left and right, naturally lying in the same horizontal plane as the front one. This gives additional advantages in work, for example, when carrying out marking work indoors.

Axis builders are convenient when working on the ground or in very large rooms; when it is necessary to draw one horizon line at a considerable distance.

Static line (plane) builders

Such devices are often called cross-liners. The beam from the source, passing through special prisms, is scattered and turns into a flat narrow stream, which is projected on surfaces in the form of lines. Most devices provide the ability to simultaneously transmit flow in the vertical and horizontal planes, so that two lines are projected on the surfaces at once, vertical and horizontal with a clear crosshair.

Two narrow flat light streams define a perpendicular intersection of planes

Such devices are extremely convenient when performing marking or finishing work - the master can constantly visually monitor the correctness and evenness of the operations being performed.

Typically, such laser levels use several LEDs and prisms, which is why they are often called multi-prism. The number of planes created can be different - from one crosshair to several (marking is carried out on several walls at once), and in addition, zenith and nadir points can be projected.

Laser levels of this type are very convenient when performing finishing work.

An important characteristic of devices of this class is the sector angle in which the plane is projected. Usually it is at least 120°, although there are modern models in which this figure reaches 160° or more. Well, the most advanced laser levels are capable of completely closing the projections of three planes they create, that is, they work at all 360°.

Some devices allow you to completely close the lines in a circle

The disadvantages of static builders include the fact that the use of prism optics and dispersion of the flow significantly reduce its intensity, and at considerable distances or on a bright sunny day, the created projections can be difficult to see, which will require the use of special additional accessories - this will be discussed later.

Nevertheless, such devices are extremely convenient and are extremely popular among professionals and amateurs, especially those involved in interior decoration.

Rotational plane builders

When working on open construction sites or in large areas, laser plane builders of the rotational type are the optimal choice to create a common horizon.

The rotating head turns the beam into a plane

The absence of prismatic scattering makes it possible to obtain a beam of maximum light intensity, and the plane is created by rotating the emitting head relative to a strictly vertical axis.

Typically, such devices belong to the professional class. Their beam transmission range can reach tens, and when using special receivers, even hundreds of meters. On a vast construction site or in a large room, it is possible to create a single horizon, thereby ensuring the simultaneous independent, diverse work of several teams.

Such devices are indispensable in large work areas.

Some “advanced” models are capable of creating both horizontal and vertical planes at the same time - they are equipped with two rotating heads.

The rotation speed of the emitter can usually be adjusted, for example, from 10 to 600 rpm.

Such laser levels (levels) belong to the most expensive category, and are not widely used in the practice of individual construction - it’s just that their capabilities in such conditions largely remain unclaimed.

What criteria should you follow when choosing a laser level?

If a decision is made to purchase a laser level, then the potential owner should already have a clear idea for what purposes he will need this tool. Such devices are quite expensive, and as their functionality increases, the price naturally increases sharply. This means that it would not be very reasonable to pay extra money for a laser level, the functionality of which will simply remain unclaimed.

When choosing the required model, you should be guided by certain criteria.

Device range

For different models it can range from several meters to several tens. Naturally, this also affects the rate of battery consumption. If you purchase a device to perform construction and finishing work in a house or apartment, then you should not chase a special range. It’s another matter if large-scale work is planned on the ground.

The range is indicated in meters. Here you need to be careful - sometimes manufacturers mean the radius, sometimes the diameter of the zone in which lines or points can be projected.

The laser radiation receiver allows you to dramatically increase the range of the device

If significant distances are required, then you should pay attention to whether the device is equipped with a special laser radiation receiver - this can significantly increase the range. It also happens that the receiver is not included in the kit, but the technical documentation reflects the possibility of using it, and the range parameters are shown with and without it, for example, 50/100 m.

Laser type

This has already been mentioned. The green beam is considered optimal, as it is closest to the maximum perception by the eye. Devices with a red beam are less expensive, but can create problems when working in conditions of bright natural radiation. The solution is to use receivers or special glasses that improve the visibility of the lines or points being created.

With special glasses, dots and marking lines will be much better visible

By the way, glasses, to a certain extent, will also serve to protect the retina from accidental direct hits from a laser beam. Of course, modern devices do not pose an excessive threat to health, but still they usually belong to class 2, that is, they cannot be considered absolutely safe.

Laser devices of the third class, with an increased range, should be used with extreme caution - their radiation already poses a serious threat to the retina.

Prices for Bosch laser levels

Bosch laser levels

If you purchase a device with red rays, you should also look at the wavelength. 635 nm can be considered optimal, but there are still outdated models in which this figure is 650 nm - even further to the periphery of the visible part of the spectrum.

If the technical documentation of the device does not indicate any information about the class of the laser used, then it is almost 100% a fake and does not deserve any attention.

Instrument error

The more accurate the device, the better, of course, but, alas, there are no absolutely ideal ones.

The error is usually indicated in millimeters for each meter of distance from the device. Expensive professional-level models can give an error within 0.5÷1 mm at a 10 m distance. For middle-class laser levels, a completely acceptable deviation can be considered from 1 to 3 mm per 10 m (usually 0.1÷0.3 mm/m is indicated)

Higher error rates are hardly acceptable - the use of such inaccurate instruments simply loses its meaning.

Installation accessories and self-leveling system

Many laser levels require installation on a tripod. It may be included in the kit or purchased separately. If you have to select it, pay attention to the size of the connecting thread - it can be ¼ or ⅝ inches.

It is necessary to take into account the diameter of the threaded connection with the tripod or brackets

It is very convenient if the laser level has the ability to be attached to various brackets - they are often included in the kit. This makes it possible to install the device, for example, on a wall surface or as close as possible to the floor surface.

Some types of brackets and stands

Magnetic fastenings are often provided - the level can be fixed on metal building structures, pipes, etc.

Using a magnetic holder, the laser level can be fixed to metal structures

Of course, the best choice would be a device with a self-leveling system. Its cost, of course, is higher, but it eliminates the possibility of making a subjective error during installation - the system will independently eliminate the existing inaccuracy. The self-adjustment range can be within 3° in relatively inexpensive models, and up to 5° in professional-class devices. If the deviation exceeds the specified values, the system will give an audible or visual (for example, flashing beam) signal.

If lines are set at an angle to the horizontal, the self-leveling system must be disabled

The self-leveling system must be able to be turned off - this is necessary when marking at a certain angle from the horizontal, say, building a staircase or performing original finishing.

Number of rays (planes) created

A reasonable approach by the future owner of the device is important here, and for this it is necessary to imagine the planned scope of application of the laser level. Ideally, of course, the more functional the device, the better, but its cost also increases in proportion to this.

If a multiprism level is selected, then it is desirable that the possibility of selectively switching on and off the created lines be provided. Sometimes extra rays create a lot of inconvenience and can even cause some confusion.

Battery life

This indicator, of course, depends on the quality of the power sources used and the characteristics of the electronic circuit of the device itself. As a rule, this indicator, provided that standard, fully charged batteries are used, is indicated in the product documentation.

It is rare that there is a need for long-term continuous operation for many hours. During breaks in work, it is quite possible to recharge power supplies, but only if nickel-metal hydride batteries are used, which do not have a pronounced “memory syndrome”. If nickel-cadmium batteries are used, they must be used until completely discharged.

A convenient option is the ability to automatically turn off the device after a certain time. For example, if no manipulations were performed, the emitter will turn off after 15–20 minutes and the device will go into standby mode. This allows you to effectively use the potential of power sources.

Parameters for using the device in “field” conditions

If the future owner plans to use the device in outdoor conditions, then you need to pay attention to some operational parameters:

— temperature range at which the laser level can be used. Some products are allowed to be used exclusively at positive air temperatures - from +5 to + 40 °C. If you plan to build in winter, you need to choose a level with a wider range, for example, from -10 to + 40 °C. Exceeding these limits will result in equipment damage.

— degree of protection of the product body. For outdoor conditions where high humidity, precipitation and increased dust are excluded, you should purchase devices with a protection class of at least IP54.

Completeness of the device

When purchasing a laser level, you need to evaluate how well its equipment matches the specifics and complexity of the work to be done. Manufacturers do not have a uniform approach to creating standard sets. Some try to offer the most complete products possible, with an almost complete list of all the probably necessary accessories. However, in individual practice, often, some accessories remain unused. Other companies offer laser levels with a minimal set (for example, the device itself, a tripod and glasses), but give recommendations on purchasing certain additional devices and devices. With this approach, it is easier to choose the optimal set for a specific area of work.

Example of a laser level configuration

Depending on the specific model, the type and scale of the work to be done, the laser level can be equipped with the following devices and accessories:

- Hard case or bag for carrying, transportation and storage.

- Glasses with appropriate filters.

- Sighting targets – for marking points at long distances.

- Laser receiver.

- A convenient option is the remote control

- Geodetic staff with a laser receiver mounting system - when performing work on the ground.

- Tripod, one-piece with telescopic legs, or collapsible. The tripod, if necessary, can be equipped with a goniometric dial.

- Brackets, magnetic suspensions and other devices for installing the device in the most convenient position for operation.

- If batteries are used as a power source, then use an AC adapter or a separate charger.

The manufacturing company and its warranty obligations

Since a laser level can be considered a fairly expensive acquisition, you should be especially careful about the brand of the product and whether it has a manufacturer’s warranty. It would also be useful to clarify the data, whether there is a technical service network in the region and how developed it is, and how warranty obligations will be fulfilled in practice.

The most reputable manufacturers of devices of this class include BOSCH and Makita. In the category of laser levels in the mid-price range, products from STABILA, Leica, Matrix, ADA and others perform well. The Geo-Fennel and Condtrol devices have received a lot of positive feedback.

If you come across a product from a company that you have never heard of before, you should not rush to buy, no matter how attractive the price may seem. It probably makes sense to look for the manufacturer’s official website, take a closer look at the product line, and read reviews on forums. If there is no clear information on the Internet, and the documentation of the device contains very vague characteristics and the manufacturer’s obligations are not completely clear, then we immediately and categorically refuse such a purchase.

At the end of the article, there is a short overview of modern models of various types that have earned positive reviews from both professionals and home craftsmen.

| Model name | Illustration | Brief description of the model | Approximate price |

| Static axis builders | |||

| "BOSCH PLL 5" | The simplest inexpensive laser level that generates one clearly visible beam. Error – no more than 1 mm/m. Range – up to 5 m. There is no self-leveling function. Laser class 2, red, 625 nm. Food: AAA elements. Weight – 0.12 kg | 2000 rub. | |

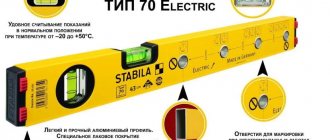

| "STABILA LA-4P" | An easy-to-use device that produces 4 directional beams. Error – no more than 0.2 mm/m. Self-leveling range - 4°. Range with receiver – 30 m. Class 2 laser, red, 625 nm. Protection class – IP51. Power supply: 4 AA batteries. Temperature range – from -10 to + 40 °C | 12500 rub. | |

| "BOSCH GPL 5 C" | 5 created beams, with an error of no more than 0.2 mm/m. Self-leveling range is 4° for 4 seconds. Range – up to 30 m. Class 2 laser, red, 625 nm. Batteries – AA. Housing protection class - IP 54. Weight - 0.6 kg. Professional grade tripod included. | 13700 rub. | |

| Static cross-liners (plane builders) | |||

| "Condtrol XLiner Combo" | A unique model that allows you to project two planes (“cross”) and additionally 5 more orthogonal rays. Self-leveling – up to 5°. The error is within 0.2mm/m. Increased range – up to 50 m, and with a receiver – up to 100 m. Class 3 laser, red, 625 nm. Operating temperature range – from -20 to +50 °C. Power: AA elements. | 13000 rub. | |

| "Makita SK102Z". | Projection of two intersecting planes (“cross”). Range – up to 15 m, with a receiver – up to 30. Self-leveling ± 4°. Error – 0.3 mm/m. Laser class 2, red, 625 nm. Power: AA elements. Weight – 0.5 kg. Includes universal magnetic mount. | 12500 rub. | |

| "Spectra Precision LG20" | Builder of two planes with a ray scan angle of 110°. Range – up to 30 m, with a receiver – up to 75 m. Self-leveling system ± 5°. The error is within 0.3 mm/m. Laser class 2, red, 625 nm. Power: AA elements. Weight – 0.6 kg. Includes case, cover, glasses, universal mount. | In the basic configuration LG20-1 – 15,700 rubles. | |

| Rotational plane builders | |||

| "Bosch GRL 300 HV" | A professional-class model that combines three possible operating modes - point, linear and rotary. Range – up to 30 mm, with a receiver – up to 300 m. Error – up to 0.1 mm/m. Self-leveling within a range of ±5°. Stepwise adjustment of the head rotation speed. Receiver and remote control included. Power supply: lithium metal hydride batteries. Includes adapter and charger. | From 68,000 rub. | |

| "Geo-Fennel FL 260VA" | Professional class model. Nadir, zenith and plane created by the rotating head. Range 40 m, with receiver (included) – 400 m. Errors: horizontal – 0.05 mm/m, vertical – 0.1 mm/m. Increased protection of the housing - IP 66. Remote control. Laser class 3, red, 625 nm. Weight – 2.6 kg. | 42500 rub. | |

| "Leica Roteo 35G" | Fully automated model with green laser, featuring the most advanced modern options. Comes with a receiver, remote control and universal mount. Error – no more than 0.1 mm/m. Stabilization device with servo drives, with a self-leveling range of ±4.5°. Leveling in two perpendicular planes. | about 100,000 rub. |

Prices for popular gasoline power plants

And finally - a video with practical tips on choosing a laser level (level)

Video: What is assessed when choosing a laser level

Checking the vertical plane accuracy of a laser level

We install the laser level about 5 meters from the wall and attach a plumb line about 2.5 meters long to the wall. We turn on the laser level and draw a line with a rope plumb line; if the deviation of the vertical line (above or below) does not exceed half the value of the “accuracy” characteristic, for example, +/- 3mm at 10m, then the accuracy of the line is within acceptable limits.

If, when checking the accuracy of the laser level, an error is found that is beyond the permissible limit, contact the service center, or carry out the adjustment yourself.

Plane plotters with cone prisms, such as the Firecore F99T-XR, can be tested using the same technology.

Preparatory work

Preparing the device for operation does not take much time. However, if you skip one of the preparatory operations, the results may be far from desired. Here is the procedure for preparing the device:

- When using for the first time, carefully study the instructions. Even if you have already used a laser level, there are subtle differences in the settings of different models.

- Accurate determination of the scope of upcoming work. This will help you understand what operating mode to set the device. For example, when gluing wallpaper, you can set only the display of vertical lines, turning off all other markings.

- When you first start the device, charge the battery or install batteries. If the device has already been used, you should check the charge level before each use of the device, so as not to unexpectedly find yourself in a situation where, in the middle of work, all the markings suddenly disappear.

Before starting work, it is worth considering the level of protection of the device from dust, water droplets and other contaminants. For example, if the device meets the IP20 protection class, you should not take it outside in wet weather. Moreover, you should not leave such a device on the street unattended.

The last aspect that you need to pay attention to is the rules for installing the level before starting work. Different models are installed on the floor (on tripods or tripods), attached to walls or ceilings. To find out how to choose a laser level, read here

Checking the 90 degree angle between vertical planes

Depending on the design of the laser level, monitoring this parameter can be divided into two techniques.

If your laser plane builder is made in the shape of a barrel and has a rotating base - a tribrach, for example, a Firecore FIR411G level, then checking the angle for compliance with the declared value between the verticals is very simple.

To do this, we install the device in the middle of the room, preferably at a distance of at least 2 meters from the walls, and make marks on the vertical lines running along the walls.

After that, without moving the device in any way, we turn the “head” of the level clockwise 90 degrees and align the verticals with the marks made earlier. If you have four vertical planes, then we drive all the verticals through the given points.

As a result, if during turns all verticals were aligned with points with an acceptable error, then the angle between them was 90 degrees. If, when rotating around its axis, one line passes through a point, and the second has a strong deviation, then the 90-degree angle is not accurately adjusted.

Laser levels with cone prisms of the Clubiona 3D type have a displaced central axis, so the first test method is not suitable here, since when turning the lines will definitely run away from the marks.

To check this indicator, we install the device on the floor and make two marks on the verticals running along the floor, the first point is closer to the body, the second at a distance of about 2 meters. Or we make one point on the floor, at the crosshairs of two verticals, and mark two points along the walls on vertical lines running at an angle of 90 degrees relative to each other.

Next, turn the body of the level 90 degrees and align the lines with the marks. We repeat the procedure until we check all four planes.

You can watch these methods in more detail in the videos below.

We bring the level into working condition

The quality of the final result directly depends on how correctly the level was placed in the working position. Therefore, first of all, you need to find the optimal place for it, and also install it as required by the manufacturer’s instructions. Therefore, we propose to consider several requirements that affect the quality of the tool:

- The device is installed so that there are no obstacles in the path of the laser. The latter can refract the beam, that is, distort the lines drawn on the plane.

- The instructions for use must indicate the maximum installation distance of the laser level from an object or plane. This indicator cannot be exceeded. But you can reduce it. This will help reduce the error in drawing lines. Therefore, it is recommended to install the device closer to the structures being repaired, on which the lines are drawn. Today, manufacturers offer laser levels with additional beam receivers that are installed opposite the device on walls, ceilings and other planes. It is this addition that allows you to increase the maximum distance without reducing quality.

- The laser level must be installed on a flat plane. It could even be a regular table. But it is better if it is a tripod or a special holder. The main task of the installation is to firmly fix the tool. The level should not be allowed to vibrate or shake during operation. This is the only way to achieve high accuracy of drawn lines and maintain the required dimensions.

The laser level must be installed on a flat surface Source gidpoplitke.ru

- Before turning on the device must be aligned horizontally. That is why manufacturers took care of the bubble level, which is located on the body of the laser level. Today, many companies offer tools with a self-leveling feature. That is, when the level is uneven, a sound is produced from inside. As soon as the horizon is captured, the sound turns off, which indicates readiness.

- Workers are warned that they are working with a laser. If the beam hits your eyes, it may cause injury.

What do you need to know to check the level?

The level, like any other measuring device, has a certain error. For a laser level it is very small, no more than 0.2 millimeters per meter.

However, this only applies to high-quality, professional models. Models are also available for sale, the error of which reaches 0.5-0.8 millimeters per meter.

To check the accuracy of the laser level. You will need a level and a tripod with a height control lever. To determine the accuracy of measurements, the level will have to be installed close to the wall in order to be able to apply marks on it.

It is important to know that the level works in two planes, X and Y. These letters can be immediately indicated on the body of the device. If they are not there, you can designate the directions yourself.

Leveling accuracy

The leveling accuracy is always indicated in the documentation of the device, and it is usually present in the description. Today the market offers levels with an error of 0.2 mm/1 m (2 mm/10 m) to 0.5 mm/1 m (5 mm/10 m). It would seem that everything here is clear and you should choose higher accuracy when comparing the price.

However, not everything is so simple: the laser line deviation error declared by the manufacturer often does not correspond to reality! Therefore, here we can only advise checking the accuracy directly in the store. Usually doing this is somehow awkward, well, here you have to choose - either seem meticulous in the eyes of the seller, or later bother exchanging the instrument.

That is why, personally, it seems to me that buying such a device on the Internet is not the best idea. Although this is influenced by urgency and the willingness to “pull the wool over our heads” with exchanges and returns.

How to check the accuracy of the laser level is described below.

Stages of checking the accuracy of the device

Carrying out measurements includes three points: checking the beam horizontally, vertically and inclination of the plane.

To check the X-ray, or horizontal, proceed as follows:

- Place the level on the tripod, turn it on and make a mark on the wall.

- Turn it 180 degrees and again make a mark on the wall close to the first one.

- Both marks must be placed on the same line.

- If the distance between the marks corresponds to the stated error. No calibration required.

The vertical Y axis can be checked as follows:

- The level is turned at a right angle so that the vertical beam coincides with the direction of the wall.

- Mark the position for the projection center.

- Rotate the level 180 degrees and make a mark at the center of the projection next to the previous mark.

- Compare the difference in readings with the accuracy of the device.

To check the device by plane inclination, the level is installed in the center of the room between two walls. Make a mark on the wall, turn the level along the vertical axis and put the mark again.

After this, the level is moved closer to the wall. In this case, the distance to the wall should be about half a meter. Marks are made in the same way. It is important not to confuse the first measurements with the second.

After this, the error in the first and second cases is determined, and then the difference between them. If at the first measurement the error was 3 millimeters, and at the second five.

Then the difference between these readings will be equal to two millimeters. This indicator corresponds to the accuracy of the device declared by the manufacturers.

How to check a self-leveling laser level?

There are models of levels equipped with a self-leveling mechanism. In such models you should:

- Carry out the first horizontal accuracy test.

- Set the level a couple of meters from the wall and make a mark taking into account the level of the beam.

- Turn the level to the right around its axis so that the left edge of the beam approaches the mark.

- Bring the right edge of the beam to the mark.

If the beam still remains on the mark, then the level is correct.

Do you know how to check if a laser level is lying? Share your experience in the comments.

Did you like the article? Subscribe to us in Yandex Zen. By subscribing, you will be aware of all the most interesting news. Go and subscribe.

Source: tradinghub.ru

How to check a laser level.

One of the main tools of a modern tiler is a device such as a laser level, otherwise it is also called a laser level or a plane builder.

If you sometimes have doubts that your laser level shows the accuracy of the lines, then to get rid of doubts, you need to regularly check the leveling accuracy of the laser level. Especially if you accidentally dropped or hit it.

How to check a laser level.

We will look at how to check a laser level for accuracy of horizontal leveling along the transverse axis using the Bosch GLL 380 Professional laser level as an example, since this is exactly the level I use when laying tiles and preparing the base.

In this level, all lines, both horizontal and vertical, are shown at 360 degrees.

To begin with, you need to understand that there are several factors that influence the accuracy of laser level leveling:

- The ambient temperature has the greatest influence on leveling accuracy. In particular, temperature changes with distance from the ground can cause the laser beam to deflect. Since the temperature difference is most noticeable near the ground, in areas longer than 20 m the measuring instrument should be mounted on a tripod.

- Also, place the measuring tool in the middle of the work area if possible.

- Along with external factors, deviations from the level can also be caused by reasons hidden in the measuring instrument itself, for example a fall, strong shocks or impacts.

Therefore, check the accuracy of the measuring tool every time before starting work. Check the leveling accuracy of the horizontal laser line first, and then the leveling accuracy of the vertical laser lines.

If during one of the checks the measuring tool exceeds the maximum permissible deviation, it must be sent to a service workshop for repair. However, according to reviews from users of laser levels and my personal experience, the workshop says that it is not possible to adjust it.

But at the same time, there is a video on the Internet that clearly shows how to disassemble and set up a laser level. See below.

And so, let's move on to the actual verification.

How to check a laser level for horizontal leveling accuracy along the transverse axis:

To check, you need a free section at a distance of 5m on a solid foundation between walls A and B.

Place the measuring device near Wall A on a tripod or strong, level base. Switch on the measuring tool in automatic leveling mode. A mode of operation in which the horizontal and vertical laser planes are emitted from the front of the measuring tool.

Point the laser at near wall A and let the measuring tool level. Mark the middle of the point where the laser lines intersect on wall A. This will be point 1. See Figure 1.

Fig.1

Next, rotate the measuring tool 180 degrees, wait until it self-levels, and mark the point where the laser lines intersect on the opposite wall B, this will be point 2.

In the next step, place the measuring tool, without rotating it, near Wall B. Turn it on and give it time to level.

Adjust the laser level in height using a tripod or pads so that the point of intersection of the laser lines exactly coincides with the previously marked point 2 on wall B.

Then, rotate the measuring tool 180 degrees without changing its height. Point the laser level at wall A so that the vertical laser line passes through the already marked point 1. Wait until the tool finishes self-leveling and mark the point where the laser lines intersect on wall A, this will be point 3.

The distance d between the two designated points 1 and 3 on wall A reflects the actual deviation of the measuring tool's height accuracy along the transverse axis.

Thus, at a distance of 2 x 5 m = 10 meters, the permissible deviation is:

10 m x ±0.2 mm/m = ±2 mm.

That is, the distance d between points 1 and 3 should not exceed a maximum of 2 mm.

How to use the level

First, the device must be configured so that it allows accurate marking.

Setting up the laser level

- Place the device on a level surface or secure it to a tripod.

- Perform horizontal leveling by rotating the screws of the bubble level. Some models have two or three levels built-in. But there are models with self-leveling. And if the level is uneven, a sound signal is given. Its absence indicates that the device is installed correctly. But this does not mean that the device can level itself. Here, too, you need to tighten the screws.

- If your level creates vertical and horizontal lines, then set it to emit both at the same time or turn off one of them.

- Some models have the ability to emit lines and dots, the shutdown of which is also regulated.

- Adjust the angle and rotation speed of the beam, if these functions are available.

- If the level can work with a laser beam receiver, then install it. Using a receiver allows you to double the range. If there is no such function, then buy a reflective plate. It increases the accuracy and range of measurements. It needs to be fixed to the object.

Disabling functions that are currently unnecessary allows you to increase the operating time of the device on batteries or on a single battery charge.

Working on the floor using a level

During construction, a laser level greatly facilitates the installation of floor joists at the same level.

- Turn on the device. The red line will show the zero level of the future floor.

- The laser level builds a line along the entire perimeter of the room. The result is a plane. Any size can be set aside from it.

- Install the logs along the laser lines.

- After installation, use a level to check the level. To do this, place the board with its side surface on the joist and direct the beam. Draw a line along it with a marker.

- Move the target to each lag. If they are installed horizontally, the laser beam will pass along the marker mark. If not, then the position of the log needs to be adjusted by raising and lowering it until the mark coincides with the laser line.

Video: Using a laser level for interior decoration

To check the evenness of poured concrete, place a pole anywhere in the room and mark on it the level that the red beam shows. Go through other points and compare the deviations of the marks.

Checking floor levelness with a laser level

Using a level, you can build straight and perpendicular lines on the floor to lay out the tiles evenly.

Laser level creates horizontal and perpendicular lines on the floor

- alignment of walls. This type of work demonstrates how outdated rulers and bubble levels are. Using a laser level, it is enough to direct the beam along the surface of the wall in any direction. Using a ruler, measure the deviation at different points of the beam;

- laying tiles. It is done similarly to work on the floor;

- construction of oblique lines. To do this, direct the beam at an angle. If this is not possible, tilt the level body. In laser levels with self-leveling mode, you need to block this function, otherwise it will interfere with work in an inclined position;

- posting decor in any room. Wallpaper and posters are aligned along the vertical beam. They make horizontal borders on the walls and hang decorative elements;

- installation of furniture, cornices, appliances. One crookedly hanging part of the interior spoils the overall impression of a beautiful room. Re-weighing using a ruler or angle takes much longer than using a laser level;

- redevelopment of premises. To install partitions, it is enough to point the beam at the installation site;

- use in measurements. You cannot measure distance with a level, but you can make the process easier. For example, if you need to find out the height of a room with non-vertical walls. You need to direct the beam upward and measure the distance between the floor and the ceiling.