The operation of the refrigerator is directly related to the circulation of freon in the system. This process is ensured by a specialized unit - a motor-compressor. If the performance of this unit is lost, or if the compressor does not start (or starts and immediately turns off) on the refrigerator, the refrigerator will not be able to perform its direct function - cooling.

However, the node does not always start due to a malfunction. In fact, there may be no breakdown at all, but the motor will not start due to insufficient voltage. Also, the reasons may be related to the breakdown of other components. For example, wiring or stabilizer failure. In this case, the refrigerator will be de-energized and will not start. If the relay clicks, but the engine does not start, there is probably a short circuit in the windings of the electrical appliance, or the starting relay itself may be faulty.

Signs of a compressor malfunction

If the refrigerator operates with irregular temperature conditions, often turns on or, on the contrary, almost never turns off, or gets very cold, this is a reason to think about the serviceability of the unit.

Usually the refrigerator compressor does not start after abnormal operation or overload. A jammed node occurs if you unplug the device for less than a minute. For this reason, we categorically do not recommend doing this.

You need to check the nodes and look for the causes sequentially. If the motor runs without turning off, the diagnostic area narrows, but this does not mean that the fault is necessarily in this unit. But, even if the reason is, for example, control sensors or relays, or a refrigerant leak, the situation cannot be ignored. In any case, working for wear, this unit will sooner or later overheat and fail.

Refilling the refrigerator with freon

You can talk about a breakdown of the compressor itself if the following symptoms appear:

- The engine hums and tries to start, but it doesn't.

- An oily puddle appeared on the floor under the device.

- The engine gets very hot, knocks, vibrates, makes noise at start and during operation.

Since the unit consists of two devices: the engine and the compressor, it is necessary to distinguish between their breakdowns. In general, motor-compressor malfunctions can be associated with:

- interturn and short circuit of the stator windings (applies to the motor);

- short circuit of the windings to the housing (also applies to the motor);

- loss of productivity;

- depressurization.

It is possible to determine what exactly happened by indirect signs. If the device operates without shutdowns, and the temperature in the chambers is high, it may be a refrigerant leak. Sometimes diagnostics show that compression has disappeared. This indicates the development of the device. It is better to replace it with a new unit.

If the compressor hums when turned on and does not start, and there are no short circuits in the windings, it is most likely jammed.

The equipment gives an electric shock

When you feel a small electrical discharge when you come into contact with the body of a household appliance, you cannot use such a product. We urgently need to find out the cause of the breakdown on the housing; there is a simple method for this: you need to measure the insulation resistance of the device using a megger

. We turn off the refrigerator and visually inspect all the wires; if the fault cannot be visually determined, we begin checking the wiring one by one.

We connect the “Ground” wire from the device to the case, and the “Line” wire – we alternately touch the wires going to the relay, thermostat, and compressor. After finding the wire where there was a breakdown, replace it with a new one. Experienced craftsmen advise that it is better not to take risks with additional insulation of a faulty wire.

The compressor in the refrigerator has broken down - what to do?

Replacing a compressor is one of the most difficult and expensive services in service centers. In addition, the spare part itself is expensive. The experience of the craftsmen and many years of observations show that if a device has a worn-out unit and there is a large output, it is better to immediately replace it with a new one. But in some cases, for example, if gaskets, rings or individual engine parts are worn out, the part can be repaired. The final decision is made by the master, based on the feasibility of the procedure.

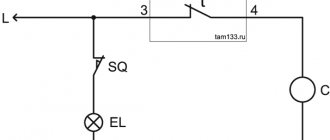

You can try to wedge a jammed compressor. For this, a specialized device is used, consisting of 2 diodes with a permissible reverse voltage of at least 400V and a maximum forward current of 10 Amperes. For example, KD 203 A, D 232 A, D 246-247.

To eliminate the wedge using this design, voltage is applied to the motor windings for 3–5 seconds. The action is repeated after 30 seconds. The device can be connected through the starting relay connectors P1, P2 or P3 or using insulated clamps. The operating principle of the design is based on the useful torque that occurs on the motor shaft when current flows through the diodes. The motor rotor begins to vibrate, the vibration is transmitted to the jammed components and releases them.

Electrical circuit diagram of a device for wedging compressors

Defrosting heating element does not work

Various problems with this part are indicated by the “F07” signal.

or three LEDs light up at once. It is worth warning users that not all error codes that appear on the display correspond to a real equipment failure - the command apparatus is just as prone to making mistakes as people. It is best to assume that the error code is just a suggestion that the defrost heating element is faulty, so everything needs to be checked.

First, we measure the resistance in the circuit, then we find out the state of the fuses, maybe one of them has blown. If everything is normal, you need to change the heating element; it is better to entrust this operation to a technician from the service center, because he will check everything carefully and diagnose the exact cause.

Is it possible to check and repair the compressor yourself?

The technology for replacing a compressor is unsafe, very complex and requires the use of specialized tools:

- oxygen-propane burner;

- pipe cutter;

- leak detector (it is also used to determine the location of the freon leak);

- electronic thermometer;

- valves for freon extraction and piercing;

- Hansen couplings;

- dehumidifier;

- pinch pliers;

- solder and flux;

- charging cylinder;

- new motor-compressor.

You should think about whether it is advisable to purchase all this to replace the compressor? Buying all the parts will cost more than the services of a repairman.

Another argument against is the high danger of the work. After all, work is carried out with gas, an explosive substance. Is it worth putting yourself at risk? Without experience and the necessary knowledge, there is a risk of damaging the tubes, releasing all the gas or disrupting the balancing.

For those who have decided to do the work on their own or are simply interested in how complex the procedure is and how it works, we will describe the technology of work when replacing a motor-compressor.

Important! We strongly do not recommend replacing the compressor yourself! This is life-threatening!

Removing the old compressor:

- Cut with a file and break off the filling tube.

- Cut and break off the capillary tube at a distance of approximately 2–3 cm from the filter drier.

- At a distance of 1–2 cm from the compressor tube seam, cut off the suction and discharge tubes; do the same with the desiccant at a distance of 1–1.5 cm from the condenser-filter seam. To do this, use a pipe cutter.

- Remove the start relay.

- Remove the compressor mount.

- Remove the compressor itself.

- Clean the pipeline.

The most common causes of breakdowns

In order to determine the cause of the malfunction, you need to pay close attention to the signs of breakdowns. This will make it possible to independently determine their source and, if possible, eliminate it.

First, you should check whether there is electricity in the network and whether the refrigerator is connected to the outlet. If everything is fine here, but the following situations arise:

- The motor does not start, but the light bulb works, periodic clicks are heard from time to time - these signs may indicate a breakdown of the refrigerator compressor. A clicking sound when starting the refrigerator indicates a broken part and the need to replace it. Audible clicks are produced by the relay that starts the engine and is responsible for its operation;

- The refrigerator starts but immediately turns off. The light is on, but the motor is not running. If there are no clicks from the start relay, then it is most likely that the thermostat responsible for the temperature level in the unit has broken down. The refrigerator control system does not receive confirmation that the temperature in the refrigerator chamber is exceeded, so the system does not start;

- The light in the refrigerator does not work and the motor does not turn on. The cause may be a broken plug or a network fault.

These basic combinations of breakdowns are not always informative; based on them, it is impossible to accurately say about the cause of the breakdown.

To determine the exact location of the breakdown, it is advisable to call a specialist. He has the necessary equipment, tools and experience to accurately identify the breakdown.

Determining the specific cause of the breakdown

A malfunction of the compressor motor is one of the most difficult breakdowns in a refrigerator. This is evidenced by the clicking of the thermostat.

If the owner of the refrigerator knows how to work with electric motors, then it is possible to ring the compressor winding - its three contacts should respond without shorting to the housing.

When traces are found between the contacts and the housing, or a resistance of less than 20 ohms is found between them, the compressor cannot be repaired. The replacement must be carried out by a technician in a repair shop.

A serious breakdown that prevents the refrigerator from starting is a malfunction of the thermostat. If there is no characteristic click when the thermostat is turned on, the contact may break and this prevents the thermostat from turning on.

If you have experience working with electrical equipment, you should find two wires that connect to the thermostat. Then the wires are removed from the terminals. We connect the wires tightly. If the device starts, it must be replaced.

Installing a new thermostat

If the problem is not resolved, then you need to check the elements of the device that are powered from the network. These are the start relay and the protection relay. Quite often they are located in a common building. The test is carried out with an ohmmeter. If a break is detected, the faulty part is replaced with a new one. If no faults are found according to this diagram, then the cause of the breakdown is the electronic circuit - only a professional can replace it.

Network faults can be one of the reasons why the refrigerator starts but immediately turns off, or does not start at all.

Normal startup of the refrigerator is carried out at a minimum network voltage of 200 to 240. If there are deviations, the device will not start. A sign of too low voltage in the network may be a very weak glow of the light bulb and a hum. If the compressor is humming - does not turn on, does not freeze, then a voltmeter can be used to determine the possible voltage.

You should also inspect the plug and power cord of the refrigerator. If there are no problems, you need to inspect the outlet to which the refrigerator is connected. To check it, you need to try connecting any household appliance to the outlet.

Atlant refrigerator compressor does not turn on

In order to avoid possible problems caused by too high or too low voltage when working with the Atlant refrigerator, a stabilizer is needed.

The reasons causing such malfunctions will be:

- damage to the socket or power cord;

- breakdown in the start relay;

- engine-compressor breakdown;

- Temperature controller failure.

Backlight does not turn on

Indesit brand refrigerators may have problems with light: although the light bulbs are not very powerful, they tend to burn out at the most inopportune moments. Replacing them is not labor-intensive - we unscrew the bolt that holds the lamp, remove it, and then unscrew the light bulb from the socket. Spare 15 W lamps

Today, the refrigerator is exactly that element without which it is simply impossible to imagine any apartment or private house. Of course, most refrigeration units operate stably and uninterruptedly for a long time, but, unfortunately, there are cases when malfunctions are observed in the operation of the equipment.

One of the most common, rightfully considered, is a sudden stop, or, in other words, the refrigerator simply stops turning on. What to do in such a situation?