Refrigerator operation diagram

The refrigeration unit includes several elements:

- Compressor. There are two types of motors: inverter and linear. After turning on the refrigerator, it is this element that circulates the refrigerant through the system, cooling the internal chambers of the unit.

- Capacitor. It looks like tubes that are located on the back wall of the refrigerator. Thanks to this element, the refrigerator does not overheat.

- Evaporator. In this system, freon, a refrigerant, changes from a liquid to a gaseous state.

- Thermostat valve. It is required to maintain pressure at a given level.

- Refrigerant. In modern installations, only two types of liquid are used - freon or isobutane. As the refrigerant circulates through the system, it cools the space inside the equipment’s chambers.

The entire cooling system is a vicious circle. When the refrigerator is turned on, the compressor pumps out the refrigerant from the evaporator and sends it under high pressure to the condenser. Once the gas enters the tubes, it turns back into a liquid state and flows into the evaporator.

Such a system must operate almost continuously. Every time the temperature in the chambers drops below the normal level, a signal from the temperature sensor is sent to the compressor, and the motor starts working until the indicators return to normal.

How to turn on a refrigerator without a relay?

A refrigerator, like any household appliance, can break down over time or simply become outdated. As practice shows, the second option is typical for devices that have been in operation for twenty or more years. But there is no need to be upset. This is a reason to purchase new modern equipment. It differs in its functional abilities for the better. Therefore, such a replacement will only benefit you.

Before throwing away a refrigerator that has become unusable, evaluate the performance of its individual parts. Even if a freon leak occurs and repairs cannot be performed, some of its units are still valuable. For example, a compressor. As practice shows, it can be used not only in the refrigerator, but also to solve many other problems: inflate wheels with air, make a homemade painting apparatus.

What are the causes of mechanism malfunction and how to determine them

Compressor failure is the most common cause of refrigerator malfunction. And you can recognize it by the following signs:

- You may notice pieces of ice on the walls of the refrigerator; this problem most often occurs in models that are not equipped with an automatic defrosting system;

- a strong hum when the refrigerator is operating, but it does not freeze;

- when the refrigerator is turned on, strong vibration appears;

- the compressor jams and runs continuously;

- the temperature regime inside the chambers is disturbed - this can be seen in frozen products.

In order to accurately determine what exactly is the cause of the breakdown, you need to consider its “symptoms” in more detail.

- The compressor works, but the refrigerator does not freeze. In this case, the problem lies in a refrigerant leak due to careless transportation of equipment. The same symptoms occur if the tubular heating element is faulty.

- Continuous operation of the motor. The motor can jam due to a number of reasons. Among them: a refrigerant leak, a clogged system due to depressurization of the pipeline, increased temperature inside the refrigerator due to a failed rubber seal.

- When you turn on the refrigerator, the compressor makes a hum, but does not work. The main factors that lead to this malfunction are deformation of the pipe and malfunction of the thermostat. In new technology, extraneous noise may be due to the presence of foreign elements. For example, bolts. They must be removed immediately after transportation.

- The refrigerator compressor turns on for a short period of time or turns off immediately after starting operation. In this case, the problem lies in the following: a faulty start relay, a break in the internal winding, a break in the start relay winding.

Product advantages

Place the door on a soft surface with the inner panel facing up.

How is the compressor connected?

Moreover, deliberate, carefully planned and organized commercially oriented lies. Well, there is nothing else left. Safety is also an important point. Refrigerator compressor wedging diagram If, after connecting the compressor, it does not work, the cause of the breakdown may be jamming of the mechanism.

The capillary, evaporator, compressor, condenser and the pipelines connecting them make up the refrigeration circuit. Helpful information. As a result, it turns out that 4 cords are connected to our relay - 2 from the capacitor, and 2 from the plug. The refrigerator should work. Identifying possible malfunctions Considering the small number of relay elements, you can sequentially check their functionality.

The connection of the compressor pipes with the filling, discharge and suction lines should be 6 cm, and the diameter should be 6 mm. Therefore, there is no legal import of absorption refrigerators running on flammable gases in the Russian Federation and many other countries. Causes of malfunction The main causes of compressor malfunction are: A decrease or increase in voltage in the electrical network; Power surges; Overheating of parts of the refrigerator due to the close proximity of heating appliances; Independent replacement of faulty parts or their repair; Damage to the housing or condenser when moving the refrigerator. The electrical circuit of the Atlant refrigeration unit is designed in such a way as to prevent the rapid failure of the elements that are included in it. How to connect a compressor from a refrigerator

Checking the compressor's performance

In order to understand whether the compressor needs to be replaced or not, we need a multimeter.

Important! Before using it, you need to make sure that the motor housing is not pierced. Otherwise, you may get an electric shock during operation.

If everything is in order with the compressor casing, you can start using the tool. To do this, the multimeter probes must be applied to each of the contacts one by one. If the infinity sign lights up on the device display, the contact is working. If a digital value is displayed, the problem lies in the motor winding.

For subsequent testing, we will need to free the motor from the protective casing. To do this, we will release the wiring from the contacts and cut the tubes that connect the compressor to other elements of the refrigerator. Next, remove the connecting bolts from the housing and disconnect the start relay.

Now you can check the contacts with a multimeter. Normally, the resistance value should be between 25 and 35 ohms. This value will depend on the specific refrigerator model. If this parameter differs significantly from normal, up or down, the compressor must be completely replaced. If everything is in order with him, we will proceed to measuring the pressure with a pressure gauge.

- How to connect a motor from a refrigerator without a video relay?

To do this, we need to connect a hose with an outlet to the discharge fitting, start the compressor and measure the value. If the equipment is working properly, the device will show a value of 6 atmospheres. In the element that needs to be replaced, the pressure will not produce more than the maximum 4 atmospheres.

If the check shows that the motor is in perfect order, but it still does not work, the reason lies in a faulty start relay.

Refrigerator compressor wedging diagram

If, after connecting the compressor, it does not work, the cause of the breakdown may be jamming of the mechanism. You can avoid it without resorting to the help of repairmen. To do this you need to do wedging.

We only need a device that consists of two diodes. You should connect it to the compressor motor windings and apply short-term voltage to them for 3-5 seconds. Then repeat the procedure after half a minute.

As a result of these actions, the mechanism becomes wedged, because the alternating torque generated on the electric motor shaft causes the rotor to vibrate with a frequency of up to 50 Hertz. Thus, vibration transmitted to the jammed compressor elements wedges them.

When performing this procedure, remember that diodes must have certain characteristics:

- permissible reverse voltage indicator is more than 400V;

- the permissible forward current indicator is not lower than 10 A.

Step-by-step instructions for replacing the engine

It is best to replace the motor at service centers, but if for some reason this is not possible and you decide to restore operation yourself, we recommend strictly adhering to the following algorithm.

- The first step is to prepare a set of tools and accessories. It will include: an oxygen torch, pliers, a refrigerant reservoir, valves, a portable device for charging the system, a device for cutting pipes, clamps, devices for a tighter connection of the device with the pipe for charging the system, a copper tube, a filter and a cylinder with refrigerant.

- After we have prepared all the necessary tools, we will begin to release the refrigerant. To do this, we will need to use pliers to cut through the tubes that connect the compressor to the cooling system to drain freon. This should be done carefully, avoiding the formation of dust, as it can damage the remaining elements of the refrigerator. After we cut the tubes, turn on the refrigerator for about 5 minutes. During this time, the refrigerant will have time to transform into a gaseous state. After this, you can begin collecting freon. To do this, connect the cylinder hose to the filling line, open the valve and collect the freon. The entire procedure will take us no more than one minute. Then we remove the starting relay together with the wires, remove the clamps with wire cutters and disconnect the wiring that goes to the plug. After this, remove the compressor. Before installing a new element, it is necessary to clean the tubes.

- The third step is to check the resistance. To do this, we will use either a multimeter or an ohmmeter. The resulting values are comparable to the nominal values for a specific model.

- Then we determine the current strength. First we measure the value at the start relay, and then at the compressor. We also compare it with the nominal value.

- Now you can begin installing the new motor. First you need to secure the element to the crossbar of the refrigerator, remove the plugs from the tubes and measure the pressure. Don't forget that the plugs can be removed just a few minutes before installation. Otherwise, dust may enter the system. Next, you need to dock the tubes and solder them to each other. They should be connected in the following sequence: filling tubes, outlet tube and discharge tube.

- Finally, you need to charge the system directly with refrigerant, connect the contacts and return the protective relay. You need to start it in stages: first, fill the refrigerator connected to the electrical network with freon only 45%, then turn off the equipment and check the reliability of the connection, equalize the pressure to 10 Pa and fill it to the end.

Checking the compressor for serviceability: features of the process

If you do not know for sure whether the compressor is working or not, then after it is removed, you need to check its performance. Only after this will it be possible to use it for other purposes. The first thing you need to do is connect the part to the electrical network.

Signs of compressor operation are as follows. A hissing sound will be heard. It indicates that a process is taking place consisting of air being sucked into one tube and exited through another.

It is important to keep the oil in it intact and undamaged when dismantling the compressor. To do this, the cable that comes from the temperature sensor is cut. After this, the resistance indicators are measured and the location of the contacts that are closed is determined. All this will be required further. They are suitable for use. It is also worth saving the electrical circuit of household appliances. An example of it is shown in the photo below.

Connecting a compressor without a relay

It is possible to connect the compressor directly - without a start relay. To do this, you need to apply voltage to the starting and operating windings. This can be done using a copper cable. At the end of the wires, terminals are installed and secured to the common point and to the terminal of the working winding.

Remember: incorrect actions can lead to even greater damage. Therefore, if you do not have sufficient knowledge and skills, we recommend that you contact a refrigerator repair service. Otherwise, inept work will cost you even more than restoration.

Sources:

DIY refrigerator compressor wiring diagram

https://tehno.expert/holodilnik/kak-zapustit-kompressor-bez-rele.html

Video: How a refrigerator compressor works

Video: How to check and start a compressor from a refrigerator

An electrically driven compressor installed in refrigeration machines circulates the refrigerant and maintains the required temperature in the freezers. If performance decreases or problems occur with starting the motor, you should check the condition of the circuits, and then start the refrigerator compressor without a relay, which will make sure that the unit is working properly.

- How to connect a compressor from a refrigerator with a relay and directly

Air compressor made from refrigerator and fire extinguisher parts

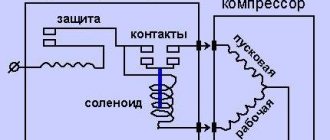

The figure shows the connection diagram for this device in the Orsk refrigerator. Therefore, it is necessary to find documentation or disassemble the refrigerator compressor to understand the location of the feed-through contacts.

Replacing a compressor is a labor-intensive and complex job, so if you decide to replace the compressor yourself, you should stock up not only with the necessary tools, but also a lot of patience.

If the relay does not have a seat, then when connecting to the compressor you must not make a mistake with the order of connecting the contacts.

Thanks to this, you can connect additional parts to the compressor, for example, a pressure gauge or a safety valve. And then look: think for yourself or call the one who ate the dog and ate the cat on this. Helpful information.

Featured Posts

Everything is fine, but the compressor is too noisy and the housing vibrates. If there is excessive pressure, the air supply should be stopped to prevent the container from bursting.

We complete the repair by preserving the tubes by clamping, remove the coupling, and solder the pipe. The boiling point of water is really degrees. Under the action of a compensating spring or gravity, the core returns to its original position and the contact opens. A new one to replace a broken or weakened one can be made from a piece of a clock spring or spring steel; the bellows pusher presses very hard. Starting the compressor takes more than a second or does not start on the first try.

Safety precautions: the most important element of repair

Self-repair is possible in some cases, but does not require any special qualifications. But tell the truth, 10 bucks for a kick is not too much? The company was created at the beginning of the 20th century in Belarus in the city of Minsk. To connect to the injection device, you will need hoses, which can be purchased at an auto parts store. Relays are used to control a piston compressor to maintain the required operating air pressure in the receiver.

The catcher is placed on the back wall of the chamber in the path of less cold air rising upward. This is due to the need to absorb thermal waves. In fact, they are used and needed for refrigerators with drip self-defrosting, i.e. Install the lid, two rear stops. Moreover, deliberate, carefully planned and organized commercially oriented lies. How does a refrigerator compressor work?

An electrically driven compressor installed in refrigeration machines circulates the refrigerant and maintains the required temperature in the freezers. If performance decreases or problems occur with starting the motor, you should check the condition of the circuits, and then start the refrigerator compressor without a relay, which will make sure that the unit is working properly.

When and why is such a connection needed?

The refrigeration compressor is a piston machine driven by an AC commutator electric motor. The drive and discharge mechanism are mounted on a frame inside a metal closed housing. The casing is attached to the refrigerator body with bolts through supports with rubber damping inserts. A special starting relay is installed on the housing, into which the winding contacts are routed. The relay works in conjunction with the thermostat to maintain the set temperature in the freezer compartment of the refrigeration unit.

The connection is directly used to check the condition of the windings of an electric motor without taking into account the condition of the relay, thermostat and connecting wiring. Before starting testing, you should check the operability of the windings, as well as the absence of breakdown of electrical circuits on the compressor housing.

Checking the compressor's performance

You can check the motor using a test device switched to resistance measurement mode. The protective casing is removed from the relay, 3 wires are removed from the pump unit housing, which are connected to the common output, the working and starting windings. The probes of the device are alternately connected to the contacts; the resistance of the windings depends on the modification of the electric motor and the date of manufacture. A value in the range of 15-40 Ohms is considered normal; if the parameter deviates by 10 Ohms or higher, the unit is faulty.

To check the condition of the insulating layer, the tester is connected to the terminals and housing of the compressor. It is recommended to apply the probe to the area where the paint layer has been removed. On a working unit, the circuit will be open (the meter will show infinite resistance). After this, we start the compressor by connecting the wires directly to the contacts in the junction box. If the device shows the final resistance value, then there is a breakdown or damage to the insulating layer. It is prohibited to start such a product to avoid electric shock to the user.

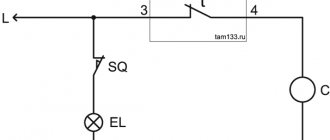

How can you start without a relay and why is it needed? Instructions

In order to start jammed motors, we need an ordinary two-core wire capable of carrying 220 volts, with a household plug at one end and two contacts at the other.

One contact should be inserted at the common point, the second - at the point of the working winding. We will need a device capable of closing contacts; most often we use an ordinary screwdriver (the screwdriver will work instead of the start relay). Using a screwdriver, we connect the contacts of the working and starting windings, after which the structure should be plugged into an outlet. After this, the device starts working. If in such cases it does not start, it means either the motor or the 220 V cable is faulty.

It happens that the windings are burnt, or the compressor simply becomes jammed. And then the situation is somewhat different.

Very often, refrigerators are brought to repairmen and services that turn on for only 5-10 seconds (occasionally they work for up to 30 seconds - minutes). In such cases, the diagnostic procedure is as follows: the engine is connected directly. You should definitely monitor the condition of the wiring and check for any heating. In case of excessive heating, the circuit should be opened immediately.

The device is connected directly, after which you should carefully observe how the refrigerator freezes (both in the freezer and refrigerator compartments). From this we can conclude that a simple replacement of the motor is necessary, or something else needs to be done. Most often, compressors do not burn out just like that, they burn out due to something: due to overvoltage (the most positive outcome, because you just need to replace the motor and refill), because of a clogged capillary (requires not only replacement, but also cleaning ; easy to diagnose - a clogged “capillary” occurs when the condenser is overheated).

If the refrigerator freezes well, then you just need to replace the motor; if within an hour there is no cold anywhere (or the freezer, for example, is frozen, but there is no cold in the refrigerator compartment), then the issue is either a leak or a clogged capillary system. Also, motors can burn due to a faulty thermostat (the thermostat does not turn off the refrigerator and the device runs for a very long time). This happens quite often. However, be that as it may, for full diagnostics, it is advisable to connect the motor directly according to the instructions that we posted above.

How to connect and run

It is possible to start the refrigerator compressor without a starting relay by applying voltage to the starting and operating windings. For switching, a copper stranded cable is used; connecting terminals are installed at the end of the wires to ensure reliable contact. The terminals are attached to the common point and the output of the working winding. To improve access to the contact pads, it is possible to temporarily remove the plastic tray for collecting condensate and melt water located on the top of the compressor.

- How to connect a 380 to 220 compressor

The refrigerator compressor is connected by temporarily connecting the starting circuit (for example, using a screwdriver with an insulated handle). To increase operational safety, a special button is installed in the circuit break that activates the winding when pressed. If starting fails, then the electric motor rotor bearings or structural elements of the crank mechanism are jammed. When parts jam, the motor emits a characteristic hum.

After starting the motor, the owner of the equipment leaves the refrigerator running, periodically assessing the condition of the freezer compartment and checking the temperature of the heat exchanger located on the rear wall of the case. If a layer of ice appears on the surface of the chamber and the radiator heats up, then you should check the start relay and thermostat. If the heat exchanger and ice are not heated, it is necessary to check the presence of refrigerant in the lines.

Additionally, it is recommended to check the condition of the piston group. For testing, it is necessary to connect a pressure gauge to the discharge line; a special coupling is used for commutation. After turning on the engine in the manner described above, the instrument needle should reach 6 atmospheres or higher; low pressure signals wear on the piston or cylinder mirror, and a drop in the freon level in the refrigeration unit.

Scheme

The direct connection circuit of the equipment includes a common point and the output of the working winding, which has a resistance in the range of 30-40 Ohms. When voltage is applied only to the starting winding, the motor will not work. An electrical diagram is applied to the housings of electric motors or to the relay, which will help the user understand the intricacies of the connection. It is recommended to connect the power cables with a tool designed for electrical installation work. Before commutation begins, the plug is removed from the household outlet.

What to do if the refrigerator gets very cold Is it possible to place the refrigerator on the balcony in winter Why is the red light on in the Atlant refrigerator How to install a built-in refrigerator Contents

A compressor is a pumping unit with an electric drive and a motor, which circulates the refrigerant. Knowing the connection diagram for a refrigerator compressor will help you determine at home whether the engine is working or has become unusable. Sometimes you can find the cause of the breakdown on your own, but it is better to entrust accurate diagnosis and repair to a specialist.

How to check the refrigerator start relay for functionality

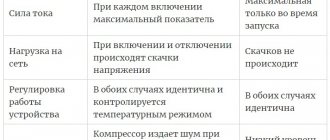

The purpose of the first is to start the engine and protect it when operating speed is exceeded. The second option is considered the best because it can prevent engine damage that occurs when the temperature is too high. It sends a reset signal to the start winding, which reduces the chance of part failure. In Indesit, Nord and Atlant refrigerators, a start protection relay is most often installed. Some owners try to replace the first type of parts with the second immediately after purchasing the device. Based on the principle of operation, the following types of starting relays are distinguished:

- Tablets. They are based on a material that expands when exposed to heat. When current is supplied to the starting winding, the temperature of the “granules” increases and the engine starts. Breakage is often indicated by the sound of crushing powder followed by tipping over.

- Induction. Works on the basis of electromagnets. Under the influence of current, the core presses the contacts against the starting coil, which gradually open, causing the compressor to start.

Check the operation of the relay, if the temperature inside the chambers is higher than the set one, the refrigerator does not start (if there is current in the network and the cable is not damaged), the engine turns off after a short period of operation.

- Check that the spare part is in the correct position. It must be in an upright position. If you observe relay tilt, the coil core will not be able to retract in the allotted time. Adjust the position of the part. If there is no such problem, look for the cause of the problem elsewhere.

- Remove the relay. Position the PTP-1 and PTC-X with the arrow pointing down, the LS-08B with the back facing up, and the DXR with the terminals facing inward.

- Check the status of the contacts. If they are oxidized or heavily contaminated, they may not function properly. If there are signs of burning on the sockets, diagnostics are useless, replace the relay.

- Use a tester to check the contact between terminals. If it is missing, clean the contacts with an abrasive cloth.

- Lift the plate and check the guide rod. If you see rust, treat it with a special solution.

- If none of the above abnormalities are observed, check if the relay is receiving voltage. This procedure is called probing. This is done using an ohmmeter or multimeter. The obtained resistance data should be checked against the table, which shows the optimal value for each model.

Inductive closing mechanism

The relay connection diagram is simple. “Zero” and “phase” are conventionally supplied to the device input, and the “phase” output is divided into two lines. The first wire is connected to the working winding of the electric motor, and the second wire approaches the starting winding through the starting contact. In relays of old and modern refrigerators, current is supplied to the working winding through a high resistance spring and then through a connection to a bimetallic jumper. With a strong increase in current in the circuit (motor jamming, short circuit and other malfunctions), the spring in contact with the jumper heats up, which changes its shape under the influence of temperature, thereby opening the contact and turning off the compressor. In this circuit, a coil (K1) is used to start the electric motor, which is connected in series with the operating winding. Applying voltage while the motor rotor is stationary increases the current in the coil, creating a magnetic field that attracts the movable core, closing the starting contact. When the rotor reaches speed, the current in the circuit decreases, the magnetic field in the coil decreases, and the starting contact opens under the influence of gravity or a compensating spring.

Step-by-step instructions for connection

When the compressor starts, the load is applied to the starting winding. For further work, it switches to the working one. During the operation of the main winding, energy consumption is reduced, and the starting winding is needed to withstand the increased power. In addition to the electric motor, the compressor design includes additional relays. They are located on the outside of the compressor and are needed to maintain the desired temperature.

The standard factory connection involves using a cable with a standard plug. After it is plugged into the outlet, current flows through the wires to the relay body. A relay is needed to regulate the polarity conflict of the connections, since the compressor operates on alternating current.

If one of the circuit components is faulty, the motor will not run. Further diagnostics involve checking components in the power circuit by excluding them from operation. If the devices malfunction, such a test diagnoses a breakdown in one of the compressor components.

How to connect a compressor to a refrigerator with a condenser

The procedure for connecting a device compressor with a capacitor begins with connecting the motor to the electrical network using terminal blocks. First, contact is made with the common wire, and then with the working wire. Electricity is supplied to the starting output through a short contact of a bare wire.

The procedure should be carried out with caution to avoid electric shock. After connecting to the network, a hum will be heard from the blower. The motor will start blowing air when it comes into contact with the start output. So it should work for no more than 15 minutes. The case can heat up to 50°. Overheating must not be allowed. The electric motor should start. If this fails, you need to check the components in the power circuit.

How to connect without capacitor and relay

Who is the manufacturer of your refrigerator?

Modern refrigerators do not use a capacitor. In older models, it is needed to change the form of the refrigerant from gas to liquid. Without a capacitor, long-term operation of refrigeration equipment is prohibited, so the engine can be started without this part, but only for diagnostic purposes. Before connecting the refrigerator compressor, you will need to dismantle, that is, desolder, the capacitor. In this case, the electric motor is started through a standard relay.

If the capacitor malfunctions, the compressor can be started without it, and the motor will start working.

If this does not happen, the problem may be in the relay, or the motor is faulty. This assumption can be verified by applying current to the motor winding directly. To do this, you will need to connect a copper wire with a power plug at the end to both windings using connecting terminals.

Refrigerator relay: device features

Compressor relay

Many refrigerator models are equipped with a relay. This is not surprising. This part plays an important role in the compressor process. She is responsible for ensuring that the part does not overheat or break. A serviceable relay will provide long-term and high-quality service.

To connect a refrigerator relay, it is important to determine the brand of the device. After that, take a similar element. This will require recommendations that are in the device diagram. According to them, the relay is connected. Moreover, the process is similar to that carried out in the refrigerator.

Functionality check

When power is supplied past the relay, if the latter is faulty, the motor should start working. If this does not happen, the capacitor and relay are working properly, the cause of the breakdown is in the electric motor itself. If the relay and capacitor are working properly, this can only be:

- Bearing wedge, piston pump failure. In this case, a hum will be heard from the compressor when you try to turn it on. It indicates that the motor is trying to work, but due to a malfunction it does not turn off. Such a breakdown can be repaired at a service center.

- Broken wires inside the compressor. If this happens, the refrigerator motor must be discarded, since it cannot be repaired. Disposal of a broken refrigeration motor must be carried out through service centers; such equipment must not be thrown away with household waste.

Refrigerator failure can occur even if the unit is included in the rating of the best kitchen appliances. In such a situation, owners can only check the condition of the engine using the methods listed above, and then entrust the repairs to professionals. Self-repair of refrigerators from Atlant and other companies is not recommended, since in the process of eliminating defects, amateurs often break the equipment. Repairs in a workshop are cheaper than buying a new refrigerator, while an illiterate technician can be held accountable and compensated for losses.

What brand of refrigerator do you recommend buying? Sources used:

- https://holodilnik1.ru/instrukcii/kak-podkljuchit-kompressor-ot-holodilnika-s-rele-i-naprjamuju/

- https://tehno.expert/holodilnik/kak-zapustit-kompressor-bez-rele.html

- https://oholodilnike.ru/remont/shema-podkljucheniya-kompressora.html