The most convenient kitchen appliance for cooking is a gas stove. But at the same time, it is also the most dangerous kitchen equipment, since during operation it consumes gas.

The gas stove should be installed at a distance from the gas pipeline of up to 4 meters, no more.

Installation of this equipment must be carried out strictly in accordance with safety regulations and operating instructions. If you have held a wrench in your hands at least once and know all the nuances of working with gas equipment, then you should not have any problems when connecting.

How to choose

Before you start buying a hose for a gas stove, you need to pay attention to a number of points and listen to some recommendations.

Gas hoses should be purchased in specialized stores that specialize in the sale of gas equipment. Such establishments, as a rule, work with trusted suppliers and sell only certified products. In addition, sales consultants have sufficient knowledge and are well versed in the intricacies of connection. Often in special stores you can submit an application for connecting a gas stove, which will be carried out by trained people

Gas hoses should be purchased in specialized stores that specialize in the sale of gas equipment. Such establishments, as a rule, work with trusted suppliers and sell only certified products. In addition, sales consultants have sufficient knowledge and are well versed in the intricacies of connection. Often in special stores you can submit an application to connect a gas stove, which will be carried out by people trained in this.

In general, the requirements for the materials from which gas hoses are made are much higher than the requirements for the production of the same water hoses. This is because gas hoses need to withstand the very low temperatures encountered when transporting liquefied bottled gas. In addition, gas models should not burn themselves and support combustion, and also have a left-hand thread.

However, the most important requirement for gas hoses is the presence of an insulating insert, which was already mentioned above. The fact is that to increase the anti-corrosion resistance of steel gas pipes located in the ground, they are given a positive potential. And there is no guarantee that one of the residents of the apartment building did not use the gas riser as grounding for their household appliance.

This situation can lead to a short circuit, heating the metal braid of the hose and creating an explosive situation. In addition to the possibility of a spark occurring in the gas pipeline and detonation of the gas-air mixture with dire consequences, a person standing at the stove can receive an electric shock, and with a significant potential of stray charges, even serious electrical injury. To prevent such situations, the set of rules SP 42-101-2003 regulating the equipment of gas distribution networks included clause 6.4 on the mandatory equipping of internal gas pipelines with dielectric inserts, which must be installed even on polyethylene hoses.

Today there are two types of stray current cutoffs. The first is represented by dielectric couplings (MD), made in the form of an insulating fitting, equipped with threads on both sides. Couplings are mounted between the main valve and a flexible hose, and are the most common type of insulator. Dielectric couplings are available in four thread sizes: 1⁄2, 3⁄4, 1 and 1 1⁄4. This variety of diameters makes dielectrics compatible with any type of pipeline fittings used in intra-house networks. Moreover, couplings are available with thread/thread, nut/nut, and thread/nut ends, which makes selecting the right fitting much easier and allows you to adapt to any type of connection.

What you need to know: valuable tips

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, a collapsible box is used, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

It is forbidden to use unnecessary connections. Independent complication of a gas structure, according to technical regulations, may entail a fine or disconnection from gas supply

If a technician has been called to connect a gas water heater or stove, it is necessary to check that the work is being done correctly: the excess tap from the tap on the lower side must be unscrewed, the flexible line must be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove .

It is also possible to use an adapter. Any additional installations are prohibited.

Description

Requirements for windows in a gas boiler room

The hose for a gas stove is a flexible pipe designed to connect a household appliance to the main gas pipeline using threaded connections. The main advantage of gas hoses is their ability to provide a tight connection in compliance with all safety requirements, as well as high elasticity, allowing the device to be moved after connection. The flexibility of gas hoses is especially important when installing kitchen units, when it becomes necessary to slightly adjust the location of the stove.

Previously, before the advent of gas hoses, the connection of stoves was carried out using steel pipes. As a result, the devices were “tightly” installed in a certain place and it was impossible to move them even a millimeter. With the advent of flexible hoses, the situation has changed radically; today, a connected kitchen stove can be easily moved to another place or turned around.

Installation requirements

Natural gas is an explosive gas, so the requirements for the premises must be strictly observed. In the room it is necessary to provide:

- the presence of a ventilation duct to remove combustion products;

- the presence of a window with an area of 0.03 m2 per 1 m2 of room, door width - 80 cm;

- the ceiling height must be at least 2.5 m, the room volume must be at least 15 m2;

- the chimney is in accordance with the standards, the pipe cross-section is selected according to the boiler power;

- the presence of a ventilation window in the door or wall with a ventilation grille of 8 cm2 per 1 kilowatt of device power;

- fire resistance of walls - 0.75 hours;

- no furniture nearby, unobstructed access to the device;

- an expansion tank must be installed at the highest point of the heating system;

- installation of a gas analyzer that is capable of blocking the access of gas in the event of a leak.

It is prohibited to install the device in the bathroom and toilet, in residential premises, and the double-circuit device in the kitchen. Devices with a power of 150 kilowatts or more can be installed only on the ground floor or in the basement. When installed in a kitchen, the area should be calculated at 0.2 m2 per 1 kilowatt of power.

Reinforced gas hose.

The gas water heater does not ignite - restoring the operation of the wick of a household gas semi-automatic water heater

The most common are rubber reinforced hoses that look like hoses for water supply. On the outside they are braided with steel threads. Although they are called rubber, they contain a polymer material inside. The easiest way to distinguish a gas hose from a water hose is by the color of the threads woven into the outer braid; they should be yellow.

Metal braided hoses are inexpensive and easy to use, but some European countries have banned their use

In our country, gas workers also recommend gradually abandoning them or using them with precautions.

The plastic hose inside is subject to the same destruction and destruction as rubber. In addition, steel is a good conductor of electric current, so the connection must be made with the mandatory use of dielectric gaskets.

Installation tips and tricks from experts

To install a gas stove, it is recommended to take hoses such that after connection, no more than 30 centimeters of the hose sag. Otherwise, it will be necessary to lay a liner, which will lead to cracking of the material in the future.

It is recommended to connect the stove to the public mains in a room with forced ventilation turned off and the windows closed. This will allow you to immediately smell a gas leak. Before installing a new slab, you need to find a stop valve for the pipe. In addition, it is not recommended to paint the hose. You can use colored heat-resistant electrical tape instead. The paint contains components that corrode the rubber shell.

Classification of gas hoses

Reinforcement of the foundation slab reinforcement pitch

A 7-meter hose for a gas stove is used when the distance from the stove to a stationary gas pipe with a tap is sufficiently large. Quite often, gas service workers, taking advantage of consumers’ ignorance of what the maximum length of the gas supply can be, “limit” it to 2 meters, unobtrusively offering the consumer their expensive services for designing an internal gas supply system and moving the riser. However, such a “restriction” for Russia is nothing more than the initiative of organizations operating in the gas supply market, and there is a corresponding regulatory document in this regard, valid throughout the Russian Federation. You can get rid of these unnecessary expenses by purchasing from us a certified hose for a gas stove 7 meters long, and, if necessary, 10 meters.

Specifications:

End parts: Nut-Nut (Female-Mother)Working medium: Natural gas/liquefied gas;Connecting size: 1/2″;End parts: nut-nut;Metal hose material: AISI 304 stainless steel (annealed, retains its shape when bent) ;Material of end parts: carbon steel Steel/9 SMN28;Operating temperature: -20…..+100 degrees Celsius;Operating pressure: Up to 1.6 MPa (16 Bar);Warranty period: 3 years;Service life: 25 years. The kit includes 2 gaskets made of paronite GOST 481-80

You can purchase these products by going to our retail store.

Connection standards and requirements

Current legislation does not determine who has the right to install gas stoves. However, the regulations prohibit the connection of such devices to a common highway without the appropriate approval.

In the apartment

Gas service employees can connect the stove in the apartment to the public mains. It is necessary to conclude an agreement with the latter in advance for the provision of such services, providing the following documents:

- technical passport for the apartment;

- certificate of ownership or a certificate from the Unified State Register confirming the right to own real estate;

- subscriber book and old contract with the gas service;

- document for a new stove and gas meter.

After signing an agreement with the service, permission is issued to connect the stove to the gas main. The procedure is carried out provided that during the inspection of the equipment installation site, no violations of current standards are identified.

In a private house

Apartment owners are required to enter into contracts with the gas service. But in private homes you can connect to an autonomous gas supply or abandon this type of fuel in favor of another or electricity. In the first case, you can avoid involving gas service employees and install the stove yourself by connecting the hoses to methane cylinders or gas holders.

But if the owner of the house wants to connect to the public highway, he will have to contact the appropriate authorities. In this case, the same rules apply as for apartments. Owners are required to first enter into an agreement with the gas service, after which the stove is connected to the main line.

Maximum length of gas hose for connecting the stove

“What is the maximum length of the gas hose?” - This is the question asked by those consumers whose gas-consuming equipment (stove, water heater, boiler, etc.) is located at a distance of several meters from a stationary metal pipe (riser). The Internet contains a lot of conflicting information on this matter. For obvious reasons, gas service employees “like” to limit the maximum length of the gas hose, in particular, to two meters, since it is more profitable for them to impose on the consumer an expensive paid service for lengthening the rigid metal main intra-apartment (or intra-house) pipe. At best, this parameter (permissible length) is fixed in the internal instructions of gas industry organizations, which in the recent past were monopolists in their service territories. But now the situation has changed. Currently, in connection with the development of the institution of ownership of apartments and private houses, and the emergence of the resulting rights and obligations among the owners, the area of responsibility of such organizations ends with the tap installed on the riser (pipe) in your apartment or house. The above-mentioned instructions are internal documents that the employees of these organizations themselves must comply with, and these instructions cannot in any way be attributed to federal legislation, which, as is known, is dominant throughout the entire territory of the Russian Federation. According to the European standard (European safety standards EN), the maximum length of a gas hose, for example for connecting a stove, is indeed limited to two meters. As for the Russian Federation, we do not have such a restriction.

How does the installation work?

The equipment installation process consists of several important steps. Let's look at each of them in detail.

See alsoFunctional kitchen design with a sofa

Selecting a location

The first step is to choose a suitable place to install the stove. A flat floor surface will ensure a level installation, which will avoid uneven cooking due to misalignment of the hob. Many modern models have adjustable feet. They allow you to install the stove evenly, even if the floor in the apartment is far from ideal.

The first step is to choose a suitable place to install the stove.

Additional Information! You can install the equipment level using a building level. If the unit does not have such legs, then you can use thick cardboard as a lining, a piece of chipboard or a wooden plank.

Important! The back of the slab should not come into contact with supporting structures.

During installation, it is necessary to provide free access to all connecting nodes so that in the event of a leak or malfunction, the problem can be eliminated as soon as possible. You also need to leave a small gap between the wall behind the slab. As a rule, the recommended size of such a gap is indicated in the instructions for the equipment.

During installation, it is necessary to provide free access to all connecting nodes so that in the event of a leak or malfunction, the problem can be eliminated as soon as possible.

See alsoSmall kitchen design - interesting design ideas

Removing the old stove

1. First of all, you need to turn off the gas valve and check whether the gas supply has stopped. 2. You need to unscrew the lock nut from the lower gas pipe. 3. The slab must be moved away from the wall. 4. The squeegee is unscrewed from the device using a key. Additional Information! If the new stove will not be installed immediately, it is better to place a plug below the tap.

See alsoDesign features of a narrow kitchen

Replacing the faucet

First you need to unscrew the old faucet without removing it completely. The window should be open, as during the process of changing the tap there will be a small gas leak. You need to prepare a piece of cloth in advance and wet it. After this, we tear off the old tap and tighten the hole with a wet cloth to ensure that the gas is shut off. Next, we prepare the thread. It should be free of rust, paint, glue and debris. A sealing tape is wound around the thread. After this, the fabric plug is removed and a new tap is screwed on. The faster the tap is screwed on, the smaller the leakage will be. It is important that there are no open flames or sparks in the kitchen.

First you need to unscrew the old faucet without removing it completely.

See also: TV in the kitchen: how to choose, placement options, tips.

Installing a new slab

The gas hose must be of high quality and reliable - you cannot skimp on it. The outlet to the stove must coincide with the hose. You need to wrap a sealing tape around the external thread of the fitting. You need to check the threads in advance. Next, the fitting is screwed into the lowering ball valve. Then you can screw the gas hose into the threads of the gas stove. After installation is complete, you need to check again that the connection is correct.

The gas hose must be of high quality and reliable - you cannot skimp on it

See alsoGerman-style kitchens: features, selection tips, best manufacturers

Connecting the stove

1. After releasing the equipment from the packaging, you need to leave only a protective film that will prevent the stove from getting dirty during installation. 2. You need to pay attention to the documents: information about the required gap between the wall and the unit should be displayed there. 3. Using a building level, you need to check the levelness of the working surface. If the stove is not installed level, you can adjust the height using the twist-out legs or, if they are missing, use improvised supports. 4. The sealant must be wound around the threaded connection of the gas pipeline and flexible hose. 5. The hose must be connected to the outlet below the tap using a suitable wrench. 6. During this connection, it is important to remember that the gasket must also be installed. As a rule, it comes with the package. This device extends the life of the gas stove, as it traps various debris. 7. Finally, you need to check whether all connections are tight enough. 8. Check the tightness.

See alsoHow to place a refrigerator in the kitchen: basic rules, important and useful tips

FAQ about boilers and heating

According to SNiP (Building Norms and Rules) 42-01-2002 dated 03/01/2005. “Gas distribution systems”, adopted and put into effect by Resolution of the State Construction Committee of Russia No. 163 dated December 23, 2002, effective date July 1, 2003: “Internal gas pipelines should be made of metal pipes. The connection to them of household gas appliances, instrumentation, LPG cylinders, gas burners of portable and mobile gas-using equipment may be provided with flexible hoses that are resistant to the transported gas at a given pressure and temperature.” That's all. No word on the maximum allowed length. The full text of this document can be found on our website HERE.

Gas hoses 3m, 5m, 7m, 10m long

Connection tools and parts

In order for the connection to be made correctly, you need to prepare the necessary tools and parts: • a flexible hose of the required length - universal - about 1.5 m, or individual rubber - from 1 m or more; • ball valve made of brass with nickel coating; • gas and adjustable wrenches; • gasket – usually included with the stove; • various screwdrivers; • sealing tape or thread – FUM tape or Loktail 55 thread is suitable; • a soap solution of medium concentration and a brush will be needed to check the correctness of the connection.

See alsoKitchen design 10 sq m in a P 44 series house with a box: arrangement options

Pitfalls of eyeliner

Just a decade and a half to two decades ago, the question of how to connect a gas stove to a distribution riser did not exist at all: domestic standards allowed only a rigid gas supply using a system of pipes, bends and angles. All this equipment was skillfully installed by gas service masters, and the stove was forever chained to its designated place. It was simply impossible to move it away, for example, during cleaning.

Flooded into our country in the early 90s. The flow of imported household appliances, including gas stoves, brought such a convenient means of connecting them as flexible hoses. The ease with which it was possible to connect the new stove to the riser was captivating. The downside of this simplicity was that anyone who considered himself a master began to take on the responsible work of connecting. The consequences in the form of domestic gas leaks were not long in coming...

Currently, flexible eyeliner has received the right to exist, secured by regulatory documents. But in this delicate area there are pitfalls that you need to be aware of.

Types of seals for gas systems

To ensure that the connections of the stove to the gas distribution system do not leak and ensure the tightness of all communications for years, special sealants are used, for example, Loctite 55 thread or FUM tape.

Gas service employees do not recommend using connecting elements made of other materials. Their performance characteristics are too weak for such an impressive daily load.

Loctite 55 thread is a practical, modern material designed specifically for reliable fixation of connecting sections in communication networks of varying degrees of complexity.

It is a sealing fiber made from high-strength complex threads, supplied in plastic containers and has different lengths (from 12 to 160 m depending on packaging).

Loctite 55 thread is a universal element that provides threaded connections with reliable instant sealing even under high pressure. The certificate allows the product to be used in gas systems without restrictions

To create a tight connection, I manually wind the thread onto a threaded section of pipeline fittings. It instantly locks in place and no longer changes its position.

The second reliable sealing element is FUM tape made of 4D fluoroplastic.

There are three types of FUM tapes on the market:

- Grade 1 is equipped with additional lubricant based on vaseline oil. It is used in industrial systems and communication networks with caustic, aggressive media.

- Grade 2 has no lubricant and works best in complexes operating on various oxidizing agents.

- Brand 3 is produced using edge fragments of the first two types and is suitable for both industrial and domestic purposes.

It consists of thin threads laid in a film.

FUM tape demonstrates high anti-corrosion qualities, exhibits good heat resistance and does not emit toxins during active use.

FUM tape allows for a strong connection of pipe elements, which will ensure complete tightness of the system for many years. The guaranteed shelf life of the tape in the container is 13 years.

Subtleties of operation

When operating flexible gas hoses, like all gas equipment, safety regulations must be strictly observed. Gas is an object of increased danger and requires the unconditional fulfillment of a number of important conditions.

The room where gas equipment is installed must be equipped with a ventilation hole, and the vent or window must open freely. This requirement is due to the need for an influx of oxygen to support combustion. Immediately after installing or replacing the flexible hose, it is necessary to ventilate the kitchen, make sure that the burner and oven controls are in the off position, lubricate all connections with a solution of laundry soap, and only then open the gas supply valve located on the main pipe. If soap bubbles appear at the threaded connections, you should immediately turn off the gas valve and take measures to reseal the joints. If bubbles do not appear, then you can proceed to a test run of the oven without removing the soap solution from the joints. This is necessary in order to monitor how the connections will behave under pressure. The burners should be lit with a special piezo gas lighter or matches. The use of gasoline models, as well as gas lighters of smokers not suitable for this purpose, is prohibited. Before lighting the oven, it is recommended to open the cabinet door and ventilate it for a few minutes. Then you need to twist the paper string, light it from the flame of a match and light the burner. After all the burners and the oven are turned on, you need to once again check the threaded connections of the flexible hose for the presence of bubbles; if there are none, remove the soap solution with a damp cloth. Burning of blue fuel should proceed evenly, without jerkiness and flashes of fire, which can lead to the release of carbon monoxide and deformation of the burners

The flame should have a bluish-violet hue without red-yellow flickers, and its height should be no more than 2.5 cm. During the cooking process, it is important to ensure that the flame barely touches the bottom of the pan and does not go beyond its limits. Otherwise, when gas comes into contact with a cold bottom surface, the effect of “chemical underburning” occurs, leading to the risk of CO2 formation

In this regard, the flame height must be adjusted. It is prohibited to heat premises with gas stoves, trust their use to persons under 18 years of age, or leave them turned on unattended. If the flame suddenly goes out, a gas smell appears, or the color of the fire changes, you should immediately turn off the main valve and call a gas service specialist. At the end of cooking, turn off the gas supply valves on the stove, and then on the main pipe. After a while, you can also close the window. It is necessary to periodically inspect flexible gas hoses and try not to miss the deadline for replacing them. It is recommended to wash your sleeves at least once a month, using a weak solution of laundry soap or soda. If a gas furnace with electric ignition begins to generate electric current, you must immediately stop using it and call a technician.

To learn how to install hoses for a gas stove, see the following video.

Instructions for self-connection

Paying a gas technician for installation work is not too high, but many home craftsmen prefer to do everything themselves. This is a feasible task that requires the purchase of components and theoretical knowledge.

To connect, you will also need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver for tightening the clamp, if required;

- sealants (Loctite 55 thread, flax, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2′;

- a brush and soap solution, which will be required to control the work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary seal against gas leaks. The narrowed edge of the plug must be adjusted to fit the hole in the supply pipe. If during the extraction process a homemade part gets stuck, you can easily remove it with a corkscrew.

Step #1: Removing the old slab

Shutting off the crane when lowering is a primary task to ensure the safety of the work being performed. Next, you need to unscrew the locknut located on the outlet and remove the coupling. If the old slab has a coupling and locknut that were previously painted, this will significantly complicate the process of dismantling them.

Sometimes it is not possible to complete this procedure, then you will need to cut the eyeliner with a grinder.

The gas stove is dismantled after disconnecting the gas main from the conductor pipe. Difficulties that arise with unscrewing the lock nut on a metal pipe can be solved by cutting off the liner

In the process of unscrewing the squeegee located in the lowering valve, it is necessary to hold the valve itself with a key. It does not have to be removed unless you plan to replace the faucet. When they plan to delay the installation of the slab, an additional plug is installed on the lower side.

Step #2: Replace the faucet

There are situations when the wall is located very close to the tap and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue doing the work.

It is necessary to prepare a piece of rag sufficient to completely block the pipe after dismantling the old tap. The next thing will be to tear it off without completely unwinding it. You will also need to prepare the selected type of seal. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the tap, the outlet from the pipe is tightly fixed with a finger and then with a wet rag. The main actions are aimed at eliminating gas escape from the pipe as much as possible. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the seal, the threads on the lower end must be thoroughly cleaned. Next, its winding is carried out directly. This process ensures a reliable and airtight fixation of the new faucet, which is then tightly screwed on. The last step is to install the previously removed handle on the faucet.

Using soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work was completed correctly, installation of the gas hose can continue.

If gas equipment is connected to the mains for the first time, you will definitely need to call a gas technician. In his presence, the equipment is checked for gas leaks when the valve is open. If the gas service worker does not find any violations, he must enter the established brand of stove into the register.

Step #3: Connecting the Flex Hose to the Stove

The external thread of the hose fitting is wrapped with a sealant. After this, it must be screwed into the tap on the branch pipe. The flexible hose is connected to the manifold at the finishing stage.

Next, the stage of test opening the tap on the lower side is mandatory to check for gas leaks. Using soap foam, the joints are treated with a brush. If foaming occurs when opening the gas tap, the work must be redone.

It is necessary to check the threads located on the manifold of the plate. Quite often it is 3/8′. In this case, you will need to install a 1/2′ adapter with a seal

If the work of replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will produce too much soot, which likes to settle on furniture and dishes in the kitchen.

How much does it cost to connect a gas stove? Is it possible to install it yourself?

When installing the stove, you need to choose the right hose taking into account the features of the gas tap. Depending on this, the connection can be either a nut-fitting or a nut-nut. Some gas stoves are distinguished by the presence of several inlet pipes, although only one is used - in this situation, the excess outlet is closed with a plug. The price for connecting a gas stove in Moscow from certified technicians starts from 1,300 rubles for a stove and from 1,500 rubles for a built-in hob.

The price for connecting a gas stove from certified technicians starts from 1,300 rubles

If you have not previously had experience connecting a stove to a gas pipe, it is better to entrust this matter to professionals

In any case, it is important to adhere to basic safety rules:

- The hose should be located in a visible place so that damage can be observed. It must not be covered with furniture or household appliances.

- It is only permissible to place a wire near the product that provides illumination or electric ignition of a gas appliance.

- Do not paint the surface of the gas hose.

- Parts made of metal must be protected from condensation and moisture, which can lead to oxidation of the product.

- Do not connect hoses made of different materials to each other.

- After installation, a little sagging is acceptable, but there should be no tension.

- The device must not be kinked or twisted.

- The connections must be tightened tightly, but without excessive force, so as not to strip the threads.

- It is better not to use the hose for an extended period - it must be replaced after the time specified in the passport.

When installing the stove, you need to choose the right hose taking into account the characteristics of the gas tap

Choosing a gas hose to connect a stove or water heater is a serious task, the competent execution of which determines the safety of not only the family, but also the entire residential building. The service life of the product depends on how high-quality the hose is chosen and on the correct installation.

It is very important to pay attention to the markings so as not to accidentally use a water hose to connect the gas. If you lack experience, it is better to entrust the selection and installation to professionals

Method of connecting the stove to the system

To independently connect a gas stove to communication nodes, special hoses with special physical characteristics are used.

When purchasing, these parts are checked for strength and flexibility, and they also look at the quality certificate to understand whether the proposed product meets the requirements for elements of gas equipment.

The stove must only be connected directly to the central gas system. The rules do not provide for any extra nodes or connections. If gas workers discover them, the owner will immediately receive an order to reconnect

In some special cases, the stove is connected using a metal connecting pipe, but this method is used extremely rarely, as it is labor-intensive and has a number of inconveniences.

Types of modern gas hoses

The hose for connecting a gas stove is not purchased at the market or at a remote point, but only in specialized stores or branded points of sale of installation equipment.

Sellers, in addition to the product itself, provide the client with information about the technical characteristics and issue a receipt, according to which, in the event of a malfunction, the product can be replaced.

When purchasing a connecting hose for a stove, you must pay attention to the markings. Elements intended for use in gas systems always have yellow identification marks.

Water hoses are marked in red and blue shades. They have much less strength and burn out in gas systems within 15-30 days after installation.

Today, in the market of related equipment, 3 types of gas hoses are the most popular. There are distinctive features between them, thanks to which the owner has the opportunity to choose the most successful option for himself.

The products are united by such parameters as flexibility and strength. Due to this, the stove connected to the system can be moved without fear of breaking or somehow damaging the gas pipeline and causing a leak.

Before installation, the slab must be inspected and determined which exit it has - angular (curved down) or straight. For an angular one, a regular hose with a standard edge is suitable, and for a straight one, you will need a piece with an angle

The rubber hose belongs to the category of the most popular connecting elements. It has a high level of strength, demonstrates excellent flexibility and is quite reasonably priced.

It is made from vulcanized rubber reinforced with textile thread. It functions perfectly in the temperature range from -35°C to +50°C and can easily withstand heavy operating loads for a long time.

The cross-section of the thread on the outlet hole of the plate must match the parameters of the connecting hose. Typically this figure is 1/2′

If the unit has a 3/8′ thread, then for correct connection to the system you will need to use a special adapter. It almost always comes with the stove. If the item is not available, purchase it from a hardware store.

The rubber hose with metal braid is an improved version of the above described option. The metal casing provides even greater strength to the product and almost completely eliminates leakage.

The product is offered on the market in the widest range and has different lengths. This allows this type of hose to be used in any kitchen area and even where the stove is used with maximum intensity.

A gas hose with a metal braid can work in aggressive conditions (heat, cold, sudden temperature changes). The metal that protects the rubber from damage has high anti-corrosion properties, does not rust and is not afraid of moisture.

A bellows hose is a flexible piece of metal-plastic corrugated tube with excellent physical characteristics. It is produced using modern technologies, is resistant to intense pressure and pressure changes, stretches well and has a high-strength surface protective shell.

The bellows hose offers an unprecedented level of reliability and ensures the safe transfer of gas from the central system to home appliances. Its service life without loss of efficiency is 25 years

The only reproach for bellows products is their rather high price compared to similar products made from cheaper materials.

However, despite this, representatives of gas distribution enterprises strongly advise owners to connect the stoves through a bellows hose in order to increase the level of safety when operating home gas units.

Additional information on the classification of gas hoses and their selection is presented in this article.

Basic requirements for hoses

The connecting hose used to connect the stove to the central gas system must meet certain requirements^

- limited length - no more than 1.5 meters;

- flatness - the surface of the part without expansions or narrowed areas;

- absence of bends , knots and twists;

- durability - service life can be found out from the seller or from quality certificates confirming the hose’s compliance with the standards generally accepted for gas equipment;

- no cracks , cuts, rust or other visible damage.

Another important point to consider is that the hose should under no circumstances come into contact with hard, sharp corners or materials prone to combustion.

It is better if it is located freely behind the stove, without adhering to any surface. Then the owners will be able to easily monitor its condition and will not miss the moment when the hose needs to be replaced.

Connection using a pipe

Connecting the stove to a centralized system using a metal pipe is a very reliable, but already outdated method. Today it is rarely used due to its complexity and the need in some cases to use specific professional equipment.

When connecting the slab to centralized communications supplying the gas resource, copper or steel pipes are used. They have a high level of strength and guarantee a clear, reliable connection

The main disadvantage of connecting using pipes is that in the future the slab cannot be moved for cleaning or moved to another place without disconnecting from the central communications.

Bellows liner

The bellows type connection is a product that meets new standards for connecting gas to a centralized system. Leading brands that sell such products offer liners made of low-carbon alloy steel, which are equipped with special locking nuts and fittings. Eyeliner can have several varieties, but their design is not much different from each other. Also read a lot of tips on construction on the blog: https://kirpich.info.

A bellows liner is a corrugated product that consists of solid metal. The service life of such eyeliner starts from 25 years. More often than not, the product lasts even longer. The liner is always checked before leaving the manufacturer's factory. In all regulatory documents today, it is this that is the standard when connecting gas equipment. This product can also heat up, but only slightly. Its temperature can rise to 40 degrees.

Conventional polymer wiring leads to fire for the simple reason that after the destruction of the hose, the escaping gas can ignite from the overheated braid. This will not happen in the case of a steel bellows liner. Firstly, the gas simply cannot escape through a solid metal pipe. Secondly, the heating level of the hose is low. Polymer wires heat up to almost 85 degrees, and this is really dangerous. In addition, the liner may be adjacent to other wires.

Varieties

Flexible gas supply can be represented by three different types in terms of quality, price and material of manufacture. The division into types is carried out according to the material of manufacture. So, the sleeve can be:

- Rubber, that is, made of rubber, additionally reinforced with thread;

- Made of steel - rubber, which has a metal braid, usually made of stainless steel;

- Bellows.

Description of rubber products

The rubber tube is made of rubber, which is completely reinforced with nylon thread. Hoses are usually sold with lengths from 1.2 to 4.

Generally speaking, rubber fabric eyeliners are the softest of all three presented. This quality can be called a disadvantage, since there is no safety margin.

The technical specifications are as follows:

- Manufactured according to the requirements of TU 23.05765871.01-92 (of course, this is for those materials that are domestic);

- Capable of withstanding pressure up to 0.05 MPa;

- Retains its properties and works normally in the temperature range from -10 to +70 degrees Celsius. It should be noted here that this is the temperature range that does not have any effect on the rubber at all. Rubber liners can work normally even at -50, but at this temperature the rubber becomes less flexible and can easily tear, or rather crack;

- Has connection dimensions G1/2”.

As for installation and maintenance, there is nothing complicated, there are only a few recommendations:

- The hose should not be in the area of the fan blowing (with hot air), in direct contact with gas appliances (of course, except for the connection point) or near the oven;

- The tightness of the connection is achieved using special paronite gaskets;

- During use, the sleeve should not be stretched or bent at very sharp angles;

- The service life ranges from 7 to 10 years depending on operating conditions.

Stainless steel

Flexible gas lines made of steel are very common today. It is represented by a tube that has a stainless steel braid. The braid has a yellow stripe. In appearance, such tubes are very similar to water products, which instead of a yellow stripe have red and blue.

At the ends of the hose there are two fittings, which, like the braid, are made of stainless steel. The fittings are inserted into the mounting points and secured with special union nuts. In this case, the tightness of the connection is achieved using special washers made of soft metals such as copper and aluminum.

Conditions for normal operation are those under which normal temperature conditions are maintained (the same as for rubber products), there are no kinks or breaks in the hose, and it has no tension.

One of the advantages of such a stainless steel liner is that it is very cheap, while being much stronger and more rigid in relation to rubber-fabric products.

Bellows liner

One of the most expensive and most reliable eyeliners. It is made in the form of a corrugated metal pipe. There are two fittings at the ends, which are secured using union nuts and sealing washers.

Capable of withstanding pressure up to 6 atmospheric units, while the normal pressure in the gas supply system is considered to be 0.03 atmospheres.

The operating temperature range is from -50 to +250 degrees. Since the bellows is, in fact, corrugated, it is not afraid of stretching. In addition, the bellows hose is capable of stretching up to 3.5 times. A normal stretch is considered to be an increase of 50-70 percent.

The bellows liner has a bright yellow color, and the union nuts and fittings have the natural color of stainless steel.

As for the scope of application, there is only one - connecting the consumer to the gas supply system.

Installation is carried out through a special insert - dielectric. Its purpose is to prevent the spread of electric current through the hose if a breakdown occurs. This insert is mounted between the consumer and the hose.

What is a hose for a gas pipe? The main requirements for the product

In appearance, the hose for connecting a gas stove is very similar to a water supply. The main difference between a gas device is the presence of yellow or white markings, which should be visible. In addition, the flexible hose for the gas stove is made of a special material. Another feature is the presence of a paronite gasket - a special ring that is used to seal the flange connection. It is the presence of the gasket that ensures the safety of using the products.

In appearance, the hose for connecting a gas stove is very similar to a water supply

Purchasing a high-quality and certified product will ensure the safe use of gas, but purchasing a hose of dubious quality without the appropriate documents can lead to tragedy. Other mandatory requirements for a flexible gas hose for a stove:

- The product must be complete, without additional couplings, extensions or connections.

- It is necessary that the flexible liner have a special coating that is resistant to hot liquids and high temperatures.

- The hose must not be subject to corrosion.

- The parameters of the product must correspond to the characteristics of the gas used.

- The service life of a gas hose for a gas stove should not be less than 10 years.

It is unacceptable to connect several hoses together - it is better to immediately purchase a hose for a gas stove, the length of which will correspond to the distance between the gas pipe and the hob. The maximum length of a gas hose for connecting a stove according to European standards is 2 meters, although a seven-meter hose is considered the longest certified product. If you look at the relevant Russian GOSTs, you will notice that they do not contain recommendations regarding the length of the gas hose. In any case, you should not install the stove too far from the gas pipe.

The main types of hoses include: oxygen, rubber reinforced, rubber-fabric, reinforced PVC hoses, bellows

Now the market offers a large number of different options for mobile gas connections. The materials used in production also differ in technical characteristics that affect their service life. Therefore, in order to understand what the hose for a gas stove should be like in a particular situation, you need to take into account the location and features of use of the hob. The main types of hoses include:

- oxygen;

- reinforced rubber;

- rubber-fabric;

- reinforced PVC hoses;

- bellows.

How to properly connect a gas boiler to the water supply system

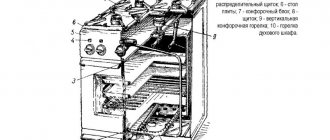

Gas heating scheme.

The connection diagram for a gas heating boiler implies a mandatory connection to the system

water supply The work at this stage is similar to connecting to a heating circuit. This step will require the use of these materials and tools:

- cleaning filter;

- American taps;

- spanners;

- sealant.

The cold water supply must be equipped with a special cleaning filter to prevent all kinds of contaminants from entering the device itself. Taps used to shut off access to the water supply must have detachable connections. Such cranes are called “American cranes”. The cold water pipes here are located on the left, and the hot water pipes on the right.

Metal hoses for gas stove

Water hoses have red and blue markings on their braid.

And finally, a bellows metal hose (Fig. 3) is the toughest, most reliable, but also the most expensive hose used for gas supply. It is this type of hose that is recommended by domestic regulations as the most resistant to gas pressure.

Rice. 3. Bellows metal hose

Whatever type of flexible hose is used for eyeliner, its internal diameter must be at least 10 mm. A modern gas stove is a fairly powerful device, and when gas is supplied through a thinner hose, it may simply not be enough for all the burners and the oven.

Installation of a gas stove and connection methods

The connection can be made using rigid or flexible hoses. In the first case, the stove is connected to the riser via an adapter coupling, in the second - a gas hose (sleeve) of the required length, which has a certificate of conformity. Regardless of the chosen method, a gas filter is installed between the ramp and the supply line to ensure complete tightness.

The type of connection determines how much it will cost to connect a gas stove in an apartment. The final cost consists of the price of the work, components and consumables - coupling or hose, seal and thread adapter (if necessary).

Separately, it is necessary to mention how difficult it is to correctly connect a gas stove with your own hands if it has an electric oven or burners. Combined equipment requires not only a safe connection to the gas pipeline, but also the laying of a separate cable with the installation of a machine and a power outlet.

Of course, who should connect the new gas stove is up to the owner to decide. But for safety reasons and compliance with legal requirements, it is better to contact specialists.

The main types of breakdowns of gas stoves and ways to eliminate them

A gas stove is a complex and dangerous type of household appliance, and any malfunctions must be treated with special attention. Common types of gas stove failures are the following:

- The burner does not light, the gas pressure is low - only the gas service can fix it

- The burner channels are clogged - it’s quite possible to clean it yourself

- The burner is not installed correctly - you can reinstall the burner yourself

- There is a gas leak - you need to turn off the gas and call the gas service

- The connections in the threads are loose - it is necessary to clean and seal the threads

- There is no tightness in the taps - it is necessary to disassemble the taps and lubricate them. If you have the appropriate skills, you can do this yourself

- The contacts have oxidized - repairs are carried out by a technician by cleaning the contacts with sandpaper

- Solenoid valve failure

- Failure of electric ignition - diagnostics are necessary to identify the cause of the malfunction

- Increased gas pressure - you need to reduce the gas pressure yourself or call a specialist

It is not recommended to try to fix the problem yourself without knowledge and experience; it is better to entrust such types of repairs to a professional technician in order to avoid more serious further breakdowns.

What documents are needed to install gas equipment?

You cannot begin installing a gas stove without the appropriate documentation. To sign an agreement for the supply of gas to your home and open a personal account with the gas service, you need to prepare a package of documents. It includes: • a certificate of state registration of a residential property and a certificate of ownership rights (purchase agreement, deed of donation); • contract for maintenance of gas equipment in the apartment; • old subscriber book (if available); • passport for the device, which takes into account gas consumption; • technical passport for housing.

After filling out all the points in the forms and reading the instructions for operating gas equipment, a gas supply agreement is signed and a permit for installation work is issued.

This documentation is submitted to the gas service for verification, after which a subscription book and special forms for drawing up a contract are issued. After filling out all the points in the forms and reading the instructions for operating gas equipment, a gas supply agreement is signed and a permit for installation work is issued.

See also Curtains for the bedroom: in life as in the photo

Main types of gas stoves

Today the household appliances market has a wide range of products. Kitchen stoves have a huge number of varieties. Gas stoves are no exception. Despite their narrow specificity, they have the following varieties:

- Gas stoves with gas oven

- Gas stoves with electric oven

A gas oven is more economical than an electric one. And electric ovens have more functions and modes than gas ovens:

- Upper and lower grill

- Food heating modes

- Defrost modes

- Steam cooking modes

- Convection mode

- Oven cleaning mode

Such a variety of modes will make cooking on a gas stove not only economical, but convenient and maximally functional.

Responsibility for independently connecting the gas stove

If the gas equipment was connected without permission, you may receive the following sanctions. 1. The supplier disconnects the apartment from the lines until a fee of 35 thousand rubles is charged for installing a gas stove and 45 thousand for installing a water heater. 2. For citizens, administrative punishment is provided in the form of a fine - 2 thousand, for officials - 3-4 thousand, for organizations and enterprises - up to 40 thousand rubles. 3. Criminal penalties include imprisonment for up to two years for individuals. 4. If the unauthorized installation resulted in the death of people - imprisonment for up to five years. The consequences of improper installation of equipment can be very serious and sad, and therefore you should not neglect the established rules.

The consequences of improper installation of equipment can be very serious and sad, and therefore you should not neglect the established rules.

With metal braid

It has an optimal ratio of price, quality and durability. Price from 140 rubles per 60 cm of finished product. The hose is made of vulcanized rubber and reinforced with textile thread. The outer part is a metal braid.

One of the most common options, the popularity of which is associated with many positive qualities, including:

- high level of reliability;

- ease of installation;

- longer service life compared to rubber products;

- large selection of lengths and diameters;

- permissible temperature has a wide range from -35 to + 50 degrees;

- ease of use.

Expert opinion Anton Valerievich Tsugunov is an all-round master, since 2003 he has been engaged in the repair and decoration of premises, more than 100 completed projects. I value quality more than quantity!

Gas services often recommend replacing old metal-braided hoses due to the inability to check the condition of the rubber under the braid. If it is impossible to confirm the relevance of the product’s service life by the passport, then I recommend replacing the eyeliner with a bellows or reinforced PVC one.

What is required to replace the stove in an apartment?

Owners often replace such large household appliances during major renovations. Naturally, the appropriate equipment is installed in Khrushchev-era buildings, which means that outdated models are replaced with more modern stoves and ovens to improve the interior and increase comfort in the kitchen.

Expert opinion

Tsugunov Anton Valerievich

Master all-rounder. Entrepreneur. 15 years of experience. More than 100 completed objects.

In addition, gas-powered appliances, according to Government Decree No. 410 dated May 14, 2013, must be replaced in the following cases:

- Equipment failure, in a situation where simple repair or replacement of jets (nozzles) is not enough.

- Non-compliance with new safety standards, which also applies to outdated Soviet models.

- Expiration of service life established by the manufacturer.

- Customer's request.

If the equipment is in unsatisfactory condition, the inspection organization will issue an order indicating the period within which replacement must be made.

The event of replacing the stove with a more modern one in the apartment should not cause difficulties. For this you will need:

- A device purchased independently, in the case where the owners do not have benefits that provide the opportunity to receive new equipment for free.

- Services of a city gas distribution organization or company that has an SRO certificate, which indicates that this legal entity is allowed to carry out activities in the field of installation and repair of gas household appliances. Personnel must have certification protocols and permits for activities related to the installation of in-house gas equipment. The company must have an emergency dispatch service.

Expert opinion

Osyka Alexander Semyonovich

Chief engineer of JSC "MOSGAZ". Candidate of Technical Sciences. Honored Power Engineer of the Russian Federation.

Based on clause 3.5 of the Moscow standard for the operation of the housing stock ZHM-2004/03 “Gas pipelines and gas equipment of residential buildings”, approved and put into effect by Decree of the Moscow Government dated November 2, 2004 No. 75 8-1111, when installing a gas hob and an independent gas oven, it is necessary to install a second shut-off device.

Gas connection Lux Highest level of safety

In civilized countries, safety requirements for gas supply equipment are constantly becoming more stringent. And this is justified, since gas does not forgive careless handling. We are pleased to offer our customers a product that meets the most modern European safety standards EN 14800:2007 and is supplied to Western European countries.

This gas supply has a number of design features that guarantee reliability and durability:

-Fittings (nuts, fittings) are made not of carbon steel (the so-called carbon steel), but of AISI 303 stainless steel. This eliminates rusting of the fittings when used in rooms with high humidity. -The bellows metal hose has an external stainless steel braid along its entire length , which acts as a reinforcing frame. -The bellows in a metal braid is placed in a protective shell that is resistant to heat. The shell expands the range of operating temperatures - this is especially important when connecting built-in gas equipment (hobs, ovens), since in built-in kitchens the hose is located in closed spaces with poor air circulation.

Ambient temperatures in such locations can exceed 100 degrees Celsius, which is already above the normal operating temperature for unsheathed hoses. Operating temperature: -20…..+140 degrees Celsius (shell heating temperature up to 120 degrees). — The protective sheath is rigidly fixed to the hose with compression sleeves.

Gas line 1/2″ in a shell: BUY RETAIL! Gas line 1/2″ without sheath: BUY RETAIL! Gas line 3/4″: BUY RETAIL! Gas line 1″: BUY RETAIL!

Connecting a gas cylinder to a stove at the dacha, where can I go myself?

This question makes you wonder where to go for help, whether you can make the connection yourself, whether this is a difficult process.

Like the connection of any gas equipment, the connection of the gas cylinder and the stove in the country must be supervised by a representative of the gas service. If it is not possible to promptly call a specialist or the application was not responded to as quickly as we would like, you can handle it on your own. But after this, you still need to call a specialist to evaluate the work of the amateur and correct any shortcomings if any are discovered.

First you need to make sure that the stove is in order, as is the gas cylinder (there should be no obvious damage, severe wear, etc.).

You should also stock up on tools:

- gas tube;

- gas reducer;

- cabinet for storing the cylinder.

The algorithm of actions will be as follows:

- The cylinder should be placed at a distance of 5 meters from the stove.

- The place for installing the cylinder must be prepared: you need to install a special cabinet and prepare fastenings.

- Now you need to connect the hose by screwing it onto the hose of the stove.

- Tighten the clamps as much as possible.

- Install the gearbox on a special adapter with wrapping tape.

- Connect the cylinder.

- Open the valve and check for leaks. To do this, use a regular soap solution: there are no bubbles, which means everything went well.