Refrigerators of the Stinol brand are reliable European-level equipment with excellent characteristics. Users noted such distinctive features of these household appliances as high-quality assembly, reliability, durability and affordable prices. But even with careful operation, various malfunctions occur with the Stinol refrigerator over time. In this review, we will look at the difficulties that owners of different models of these kitchen units face.

The principle of operation of the refrigerator

All refrigeration equipment operates on a similar principle, performing two main tasks: concentrating cold in the inside of the device and removing the generated thermal energy outside. In modern equipment, freon is most often used, a popular type of refrigerant.

Freon includes fluorine, chlorine and ethane. This refrigerant has a unique quality: it changes from a liquid to a gaseous state when the pressure within the system fluctuates. The cooling procedure is as follows.

- The compressor draws the refrigerant inside.

- The piston pushes it through the tubes.

- During the heat transfer process, the refrigerant begins to condense.

- Freon becomes liquid.

- Moisture is absorbed by the sorbent, turning into gas.

- Next, the refrigerant enters the capillary tube.

- The pressure drops along with the temperature of the gas.

- Passing through the evaporator, freon changes its properties.

- The refrigerant in a gaseous state again enters the compressor.

On sale you can find models with two compressors - one for the main chamber, the other for the freezer. On the one hand, the efficiency and quality of cooling increases noticeably, but on the other, maintenance and repair of equipment becomes more complicated. The refrigerator can also be equipped with a drip system or NoFrost technology.

Compression models are the most common solutions on the refrigeration market. Here, the movement of freon is organized by changing pressure. But there are other types of refrigeration systems:

- adsorption;

- steam ejector;

- thermoelectric.

Adsorption technology uses ammonia as a refrigerant. The obvious disadvantages of such devices are problematic maintenance and unsafe substances. Systems of this type were used in old equipment that has already been discontinued.

In steam ejector refrigerators, water runs through the tubes, and the ejector plays the role of a pump. The system is stable, safe and environmentally friendly, but consumes a lot of electricity and liquid to raise the temperature.

Thermoelectric models operate on the principle of the Peltier effect: heat absorption through two conductors and current. The system is reliable, durable, but very expensive, as is its maintenance.

Electrical diagram of a refrigerator with No Frost system and self-defrosting

The refrigerators described above have a drip defrosting system. This means that the refrigeration chamber is equipped with a “crying” evaporator: when the compressor is idle, the frost on it melts naturally, because the temperature in the chamber is positive.

The resulting water flows through special gutters through a tube into a container located above or near the motor. Later, the running motor becomes very hot and the water evaporates. A freezer with such a system never thaws on its own, and frost forms not only on the walls of the chamber, but also on the food.

No Frost refrigerators do not need to be defrosted; you will not see frost in their chambers, even in the freezer. A characteristic feature of such models is the presence of a fan that distributes cold air from the evaporator among the chambers.

The cooling coil itself in such models does not look like the usual solid metal plate, but like a car radiator or the condenser coil on the back of old refrigerators.

In the general operation scheme of the refrigerator, the new elements behave as follows:

- the fan or turbine starts together with the compressor and evenly distributes cold air among the chambers;

- when the thermal relay opens the contacts supplying the engine due to the achievement of the set temperature, the fan is simultaneously turned off;

- Once every 8 - 16 hours the thermal relay turns on the heating element. This is an electrical mat or wire that heats the evaporator coil to remove frost from it. Warm

- air does not enter the refrigerator chambers, since the evaporator is hidden and the fan is turned off;

- when all the frost has thawed, the temperature compensation switch turns off the heating;

- Additionally, the thermostat can control a damper that regulates the supply of cold air into the main chamber through the channels.

Defrosting such refrigerators is similar to a “crying” evaporator in only one way: the resulting water also flows through the channels into a container near the motor.

The scheme described above is the most primitive. Most modern models are controlled centrally, from an electronic board.

The main disadvantage of No Frost refrigerators is the drying out of food due to constant air circulation. Everything has to be stored in containers with tight lids or wrapped in film.

An original solution to the problem is offered by Electolux in the Frost Free system. In these units, the freezer operates according to the No Frost system, and a classic, “crying” evaporator is installed in the chamber with a positive temperature. The electrical circuit is generally identical to standard “no frost” systems.

Compressor electrical system design

The main element of the refrigerator is the engine. It is necessary to organize the circulation of the refrigerant, and in our case, freon, through the pipes. In addition to the unit itself, the system contains the following elements:

- start relay;

- thermostat responsible for a specific temperature level;

- protective relay to prevent engine overheating.

The engine includes a rotor and starter. The design of the latter consists of several copper coils. Whereas the rotor is more like a regular steel shaft working in tandem with the engine's piston system.

When the unit is turned on, electromagnetic induction is formed in the coils, which serves as a source of torque. Next, the rotor begins to rotate due to centrifugal force, and at the same time the piston moves.

In modern models, the engine is located inside the compressor, which minimizes the likelihood of spontaneous refrigerant leakage. The system in its original form is subject to strong vibration. To reduce it, a special metal suspension on springs is provided.

On new models, the latter are fixed inside the case, while on old ones - outside. The first option is more practical and allows you to dampen vibration noticeably more effectively. But in the event of a suspension failure, organizing repairs is much more difficult.

Refrigerator compressor Stinol

The motor will operate until the required temperature is established in the chambers, after which the thermostat is connected. It opens the contacts and current stops flowing to the motor. The compressor also stops working. When the temperature rises, the thermostat contacts will close again and the cycle will continue.

In models of the mid-price and budget categories, the thermostat quite often fails. The element does not have the most complex design and costs a penny, so it is much more practical not to repair it, but to buy a new one.

How_to_remove_the_refrigerator_start_relay_stinol

> Construction

Today, Stinol refrigerators are one of the most popular models available on the domestic market. Despite belonging to the Italian company Indesit, the production of household appliances Stinol 101 takes place at a plant located in Lipetsk.

It appeared in 1988; at that time, only 7 different models of refrigerators came off its container. Gradually, the volume of manufactured products increased, the model range expanded significantly, and the brand gained recognition among the population.

Refrigeration unit diagnostics

To find out the possible cause of the problem, it is necessary to carefully examine the unit for the working condition of the elements:

- check the main components for corrosion of parts, deformation, mechanical damage to components, damage to protective coatings;

- examine the device for tightness, fastening strength of parts and automation devices;

- check 3 functional parameters of the device: temperature in the freezer and near the back wall of the cabinet, power consumption.

Frequent problems with Stinol refrigerators

The entire model line of refrigeration units is distinguished by reliability, functionality and high build quality. However, they, like kitchen appliances from other brands, are not immune to various breakdowns. Let's look at typical faults typical for the Stinol line.

Cabinet breakdowns

If the cabinet is faulty, a thin layer of frost will accumulate on the static evaporator. As a result, a significant amount of liquid accumulates in the condensate container.

Defects in this state of the refrigerator are explained by a violation of the seal of the chamber due to:

- rupture or loose seal;

- deformation of the refrigeration unit structure;

- the presence of gaps between the rubber door seals and the surfaces of the freezer.

Possible problems with the sealing rubber can be repaired using a hair dryer with a power of 1-1.5 kW. To do this, you need to heat the rubber seal in the contact area with a hot jet. Then stretch it so that the shape of the part changes. After manipulation, the door must be closed. The refrigerator can be used after the seal has cooled down. If the protective layer is torn, it should be replaced.

Poor seal seal

Malfunctions of electrical circuit and automation elements

Very frequent breakdowns occur with automation devices and electrical circuit components. These include:

- faulty starting or thermal relay;

- breakdown of the compressor, fan and other components;

- reducing the insulation resistance of the electrical circuit;

- malfunction of the thermal fuse or defrost heater in equipment with the No Frost system;

- defect of freezer, timer;

- breakdown of the evaporator pan heater;

- clogging of the drainage system with small particles.

Troubleshooting automation in a Stinol refrigerator consists of identifying the defective element, repairing it, and if it is impossible to repair the breakdown, replacing the part with a new spare part.

Problems with refrigerant

If the volume of refrigerant is too high when filling the device, then the temperature in the freezer remains less than -180C, the refrigerator compartment is cold, and the return pipe becomes covered with condensate or a layer of frost. To normalize the operating process of the device, after a two-hour run-in, the dose of freon is adjusted.

In the event that the filling dosage, on the contrary, is underestimated, the refrigerator is warm and the temperature is reduced by more than -250C. In this case, frost may partially form on the rear wall. Just as in the previous case, it is necessary to dose the lack of refrigerant to normal.

If a refrigerant leak occurs, oily spots appear in these places. The solution to this problem is to fill the unit with refrigerant or replace the assembly component with a new part.

Warning! Freon vapor is a poisonous gas, so it is taken from the refrigerator into special cold receivers. After any work with refrigerant, the room is ventilated for at least 15 minutes.

Signs of problems with the refrigerator and possible malfunctions

There are several typical breakdowns of Stinol units, which manifest themselves according to certain signs. In the table we look at the main problems with refrigerators of this brand and how they manifest themselves:

| Sign | Possible defect |

| The device does not turn on | faulty electrical plug or power cord; breakage of compressor windings; The thermostat or start-protection relay does not function; open circuit of the thermal fuse; timer jamming in defrosting mode; contact failure occurred in the electrical circuit connection due to oxidation |

| After a short period of operation the unit switches off | break in the starting winding of the electric motor; The bimetallic plate of the protective relay or the starting relay coil do not function |

| The device freezes slightly | The temperature regulator does not work; the rubber seal has lost its elasticity and shape; the compressor has reduced performance; the capillary pipeline or filter-dryer is clogged; the integrity of the electrical circuits is compromised |

| The refrigerator is too cold | the fast freeze button is stuck; The thermostat knob is not adjusted |

| The freezer freezes, but the second chamber does not | there is a refrigerant (freon) leak; the system has depressurized |

| It's warm inside the freezer (refrigerator without NoFrost system) | The motor-compressor for the freezer broke down |

| Moisture collects at the bottom of the device | violation of the tube position; clogging of the outlet tube with small particles |

| It’s warm inside the freezer (appliances with the No Frost system) | NoFrost automatic defrosting system defect |

Let's look at the most common faults of some models

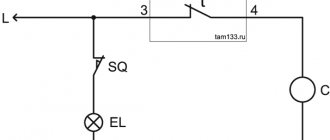

- Two-chamber refrigeration appliance Stinol 102. The device has two compressors with a unique NoFrost freezer defrosting system. The front panel is equipped with two thermostats. A special feature of the model is the circulation of air between the freezer and the evaporator fins due to the electric fan. Frequent equipment breakdowns include a malfunction of the thermal relay (in the TN1 or TN2 circuit). To verify that the part is faulty, you need to remove the wires from contacts numbered 3, 4 and connect them with a jumper. If after the manipulation the compressor starts, there is a breakdown in the relay. It may be that the equipment does not cool when the compressor is running and the condenser is cold. In this case, there may be a freon leak.

- Stinol 103. A typical problem with refrigeration units of this model is the failure of the temperature controller. This is due to the technical characteristics of thermoelements, which are designed for a five-year service life. Due to this defect, the temperature in two chambers may be elevated, as a result of which the unit will behave unstably. Over time, the connections of the electrical circuit may be damaged due to oxidation or burning of contacts, various breaks and other breakdowns. If the starting or thermal relay fails, the compressor does not turn on.

- Stinol 110 is the most common model. The refrigerators consist of a spacious refrigerator compartment and a small freezer, which is equipped with the NoFrost system. Typical breakdowns of this unit are no different from those of the 102nd model. The thermostat T1 and timer TIM-0 may be faulty.

Rules for repairing relays for the Stinol refrigerator

Today, Stinol refrigerators are one of the most popular models available on the domestic market.

Despite belonging to the Italian company Indesit, the production of household appliances Stinol 101 takes place at a plant located in Lipetsk. It appeared in 1988; at that time, only 7 different models of refrigerators came off its container. Gradually, the volume of manufactured products increased, the model range expanded significantly, and the brand gained recognition among the population.

Features of Stinol refrigerators

Those who have already purchased household equipment for cooling food from Stinol note their following properties:

- Reliability.

- Duration of operation.

- Many color options.

- Presence of an anti-corrosion layer.

- Extensive model range.

- Impressive refrigerator volume.

- Economical use of space.

- Strength of raw materials.

- Introduction of an automatic defrosting system (No Frost or drip).

- Compliance with international quality standards.

relay for refrigerator Stinol

To all these positive aspects you can add an acceptable cost. Due to the technologies used, maintaining Stinol refrigerators is quite easy. They need to be defrosted no more than once every six months. The rest of the time this procedure is carried out automatically.

The shelves can be removed and cleaned from dirt using a dishwasher. They are made of impact-resistant glass and framed with a metal frame. As a result, it is possible to put dishes that require a lot of space in the Stinol refrigerator. Convenient handles, which are not recessed, allow you to easily open the household appliance even with your hands full.

Where are the relays located?

It should be noted that these units belong to class A or AA, which means their low energy consumption. Stinol refrigerators operate in quiet mode; an increase in noise effect is an indicator of a malfunction. In case of power outages, they are able to withstand the load and maintain a low temperature in the Stinol refrigerator and freezer for a long period.

Design of the Stinol unit

The operation of the refrigerator begins when it is plugged into the network. By means of the starting relay of the compressor of the Stinol refrigerator, the compressor motor is started, which causes the flow of refrigerant into the condenser. This is due to the interaction of suction and discharge type pipelines.

Design of the Stinol unit

The refrigerant then passes to the filter, dryer, evaporators and capillary tube. Next, the distilled substance changes its state of aggregation, turning from liquid into vapor. Then everything repeats again. The temperature is regulated using a thermostat. The connection to the power supply is indicated by an indicator that indicates the operating mode by means of a green color. Example in the photo.

Diagnosis of starting relay faults

Despite the fact that the manufacturer does everything possible for the long-term operation of Stimol refrigerators, over time they still fail. The starting (thermal) relay often suffers. There are many reasons for this, and only diagnostics will help identify them. It should be carried out independently only if you have experience in such work. If it is not available, you must contact a professional technician.

Relay test

Diagnosis is carried out as follows:

- Inspect all the main elements (contacts, rod, coil with core, mount with compressor) to determine the location of the damage. Problems with the operation of the start relay can occur due to exposure to moisture, high temperatures and mechanical damage.

- Check all joints and fastenings of the automatic system.

- They measure the temperature in strategically important places (the back wall of the Stinol refrigeration unit, the freezer).

- The power value is recorded.

Performance diagnostics

The data obtained becomes the basis for determining the exact cause. Identifying a defective part is the first step in solving the problem. A competent approach allows you to quickly return the Stinol refrigerator to operating mode. If this is not possible, then all that remains is to replace the damaged start-up relay of the Stinol refrigerator with a new one.

Repair of starting (start-protective) relay

You should suspect the thermal relay of the Stinol refrigerator if problems arise with a household appliance in the following situations:

- Lack of response to turning on the Stinol 103 refrigeration unit. If the start-up thermal device is in order, then the cause must be sought in the power supply circuit or in the thermostat;

- Difficulty starting the compressor. It either does not turn on at all, or turns on and after a few seconds exits the operating mode;

- Noisy motor operation. The thermal relay turns on intermittently due to problems with the compressor. As a result, it wears out faster and fails;

- The temperature in the freezer compartment of the Stinol refrigerator is too low. Additional symptoms include insufficient regulation by the thermostat, noise during operation of the compressor and thermal relay, and increased electricity consumption. The reason for this phenomenon is sticking of the contacts of the starting or start-protection relay. If the problem is ignored, serious damage to the compressor motor and its subsequent replacement may occur;

- Short operating cycle of the Stinol 103 household appliance. Signs of a malfunction include slight freezing of the Stinol freezer, frequent shutdown of the motor, problems with condensation, and failure of the thermostat.

Checking the Thermostat

The temperature controller often fails. This is due to the fact that the thermostat of the German company Ranko, which was installed in the refrigerator, has a short working life - approximately 5-6 years. If the temperature controller in the refrigerator is not working, the compressor will not start. To exclude other breakdowns, it is necessary to check the serviceability of this part.

At home, it is difficult to check whether the device is working or not. However, there are 2 ways to determine the operating status.

- The regulator contacts numbered 3 and 4 (in the diagram of the 103rd model they are designated as TH 1 or TH 2) must be closed. Thanks to this, the integrity of the electrical circuit and the supply of mains voltage to the compressor input (in the CO 1 or CO 2 circuit) are maintained. It is necessary to determine whether the supply voltage is supplied to the regulator contacts. If it is not there, then the integrity of the entire circuit from the electrical outlet is checked; if there is, the power is turned off and the contacts are dialed. If they break, the part must be replaced.

- You can also short-circuit the thermostat input contacts. If the compressor starts working, the regulator is faulty. Otherwise, the breakdown did not occur to him. The malfunction is also determined by ear: when the thermostat switch is mechanically turned, a click occurs. If it is not there, then there is a high probability of a spare part malfunction.

Any malfunction of a refrigeration unit whose service life is more than 10-15 years requires a thorough inspection by a specialist. Repair of Stinol refrigerators most often involves replacing a worn-out part. If you have experience in electrical installation work, you can replace the spare part yourself. But when breakdowns occur too often, you should think about purchasing a more modern version of the refrigeration appliance.

Electrical circuit of a smart refrigerator with electronic control

Classic thermostats, with a mechanical rotary knob and a bellows inside, are becoming less and less common in modern refrigerators. They give way to electronic boards capable of managing an ever-increasing variety of operating modes and additional refrigerator options.

The function of determining temperature instead of a bellows is performed by sensors - thermistors. They are much more accurate and compact, often installed not only in each refrigerator compartment, but also on the evaporator housing, in the ice maker and outside the refrigerator.

The control electronics of many refrigerators are made on two boards. One can be called user: it is used to enter settings and display the current state. The second is system, through a microprocessor it controls all devices of the refrigerator to implement a given program.

A separate electronic module allows the use of an inverter motor in refrigerators.

Such motors do not alternate cycles of operation at maximum power and idle time, like conventional ones, but only change the number of revolutions per minute, depending on the required power. As a result, the temperature in the refrigerator chambers is constant, electricity consumption is reduced, and the operating life of the compressor is increased.

The use of electronic control boards incredibly expands the functionality of refrigerators.

Modern models can be equipped with:

- control panel with or without display, with the ability to select and set the operating mode;

- multiple NTC temperature sensors;

- FAN fans;

- additional electric motors M - for example, for crushing ice in an ice generator;

- HEATER heaters for defrosting systems, home bar, etc.;

- VALVE solenoid valves - for example, in a cooler;

- S/W switches for controlling the closing of the door and turning on additional devices;

- Wi-Fi adapter and remote control capability.

The electrical circuits of such devices are also repairable: even in the most complex system, the cause of a malfunction is often a faulty temperature sensor or similar small detail.

If the refrigerator “glitches” and refuses to correctly execute the specified program, or does not turn on at all, most likely the problem concerns the circuit board or the compressor; it is better to entrust the repair to a specialist.

Do you want to understand better than others?

- Schematic electrical diagram of the Gorenje refrigerator - Schematic electrical diagram of the Gorenje HZOS 3361/6 refrigerator Standard electrical diagram of the refrigerator Let’s consider the principle of operation using the example of a standard classic…

- Schematic electrical diagrams of Indesit refrigerators - Schematic electrical diagram of the refrigerator Indesit B16 NF.025, C 132 NFG.016, C 138 NFG.016 L - phase, N - neutral, TH1 - thermostat, RH1 - thermal relay...

- Schematic electrical diagrams of Biryusa refrigerators - Schematic electrical diagram of the Biryusa 18 S M refrigerator - compressor KV-120 K - relay P1 T - thermostat TAM133-1M S - switch VOK-2 L - lamp 15W...

- Circuit diagrams of Hotpoint Ariston refrigerators - Circuit diagrams of the Hotpoint Ariston MB 2185 NF.019 refrigerator L - phase, N - neutral, TH1 - refrigerator thermostat, TH2 - freezer thermostat...

- Schematic electrical diagrams of Daewoo refrigerators - Schematic electrical diagram of the Daewoo FR-3501 refrigerator Schematic electrical diagram of the Daewoo FR-3801 refrigerator Schematic electrical diagram of the refrigerator…