Engine location

The horizontal layout is used, while in light hammer drills it is vertical. medium not heavy. However, there are no exceptions. Heavy hammer drill

Metabo KHE ninety-six, weighing almost twelve kg, has a horizontal engine.

A tool with a horizontal layout is more compact and not convenient for working in narrow spaces. However, this design is characterized by an increased shock load on the engine and somewhat worse cooling conditions.

The vertical layout provides better engine operating conditions (reduced shock vibration and effective cooling), in addition, a wider range of motion of the piston without the striker due to the ability to use it instead of an oscillating bearing

crank mechanism with increased piston stroke.

Rotary hammers with a vertical engine can withstand more intense work than models with a horizontal layout.

Rotary hammer power plant

The work uses a commutator type electric drive. Depending on the power of the model, a horizontal or vertical engine mounting scheme can be used. In the first case, we are talking mainly about light-class models for household use. This technical solution is simple and convenient (especially when you need to work in places with difficult access). Among the disadvantages of this option, it is worth highlighting insufficient engine cooling and high load on the power plant.

The advantage of a vertically located electric motor:

- Reduced vibration level;

- More intensive cooling (which is especially important for high-power equipment).

- In tools like this, such as the Makita HR3200C, the piston always moves with a larger amplitude.

This tool is designed for long-term operation under difficult operating conditions.

You can find out more: “What is the difference between an impact drill and a hammer drill: 7 main criteria”

Impact mechanism

There are two main versions of the shock electro-pneumatic mechanism. using a swinging (drunk) bearing, in other words, a crank mechanism. Instructions and video

on the topic of how to properly disassemble

hammer drill

repair. The first option is used for light and, in part, medium hammer drills, the second. for medium not heavy.

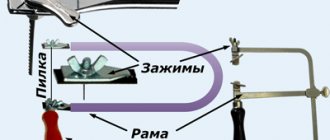

The figure below shows a diagram of a light-type rotary hammer. Its impact mechanism consists of an oscillating bearing

, piston, ram is not striker.

During operation of the hammer drill, rotation from the electric motor is transmitted to the inner sleeve of the swing bearing . At the same time, its outer sleeve, together with a perpendicular axis connected to the piston, performs oscillatory movements. Between the piston and the ram there is an air space, which, thanks to the increased pressure and rarefaction created here alternately, forces the ram to repeat the oscillatory movements of the piston, striking the striker. The latter again hits the tool located in the chuck. Thus, the energy of the electric motor is transformed into the impact energy of the tool.

The pneumatic impact mechanism is equipped with a self-shutoff function when idling. Office, when the tool (drill, drill, bit) is not pressed to the surface being processed, the ram moves forward, opening a hole in the body for air to enter and exit. And therefore, this compression and vacuum are not created in the working air cavity, it is turned off, and the hammer drill

works without shocks. When the tool is pressed on the surface being processed, the hole is blocked by the ram, compression occurs in the air cavity, and the non-impact mechanism begins to function.

Determining which hammer drill is better

The first electric hammer appeared back in 1932. Since then, its design has remained virtually unchanged. The main elements remain to this day: electric motor, impact mechanism, gearbox and cartridge. Time and progress have only increased the electronic muscles, simultaneously replacing the material of the case and mechanisms.

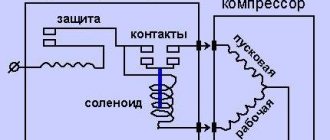

The main function of this device is impact. According to the method of its implementation, there are electromagnetic and pneumatic hammer drills. Electromagnetic beats are produced by two interacting electric coils. The reciprocating motion from the coils is transmitted to the core, which in turn acts on the drill. In pneumatic devices, the shock occurs when the piston moves back and forth in the cylinder. A household hammer drill is usually equipped with a pneumatic impact mechanism.

Depending on the type of drive, the following devices are distinguished:

- electrical network (powered by the electrical network);

- electric rechargeable (battery operated);

- pneumatic (used in fire and explosion hazardous work);

- gasoline (used in road construction).

The most widespread is the electric network type with a pneumatic mechanism; it is also called a household hammer drill.

Based on the number of modes there are:

- single-mode, only drilling mode is present;

- dual-mode, drilling mode and hammer drilling mode;

- three-mode, have a drilling mode, hammer drilling, and chiselling mode.

How does a hammer drill work? What's inside a hammer drill? Using the DeWALT D25603K rotary hammer as an example

How does a hammer drill

?

What happens inside a hammer drill? How does a hammer drill

? Operating principle of perforations

In medium and heavy hammer drills with a vertical engine layout, the piston is driven by a crank mechanism. The increased amplitude of movement of the pistons contributes to a higher impact power, which for heavy hammer drills can reach twenty J. The operation of the impact mechanism occurs in the same way as described above.

At the end of the article there is a video demonstrating the operation of the impact mechanism.

The figure below shows the structure of a domestically produced hammer drill Progress PE-40/1050, with a power of one thousand fifty W with a vertical engine and a crank drive of the impact mechanism. Rotation from the engine is transmitted through a worm shaft to a helical gear, on the shaft of which there is a crank that drives the piston.

Hammer gearbox and chuck

It will be useful to read: “What is the difference between an impact drill and a hammer drill: 7 main criteria”

A rotary hammer gearbox is a device that performs the function of transferring the driving torque to the chuck. Depending on the installation they are:

- cam (to change the nozzle, a special key is used, which allows you to bring the cams together and apart);

- quick-release (do not require the use of additional tools to replace the hammer drill);

- SDS systems (this option is used in 90% of cases, as it is distinguished by the high speed of replacing the actuator: just insert it into the socket and turn it).

The ease of use of the tool, the speed of drill replacement and, ultimately, the productivity of the builder directly depend on how the hammer drill chuck is designed.

The technical characteristics of the power tool will help you choose. Depending on each of the above parameters, its performance and functionality are determined.

| Specifications | Range of values | |||

| Power | household models | 400-1000 W | ||

| professional models | 1-2 kW | |||

| Impact force | 2-25 J | |||

| Rotational speed | household models | 1500-2000 rpm | ||

| professional models | 2000-4000 rpm | |||

| Beat frequency | 2000-6000 beats/minute | |||

| Cartridge | SDS+ | drills up to 28 mm | ||

| SDS max | drills over 28 mm | |||

| Weight | 2-15 kg | |||

All this will allow you to evaluate the possibilities of choice in accordance with the tasks and their specifics and find the optimal option in all respects.

Safety clutch

Two types of clutches are used as safety clutches in rotary hammers: friction and spring-cam. The former consist of disks that are normally pressed against each other and transmit torque. When the tool jams, the disks slide relative to each other, disconnecting the motor shaft from the chuck with the attachment. The friction clutch is used, for example, in models from Metabo.

Many companies use spring-cam type safety clutches. They consist of two coupling halves with radially located projections and depressions (teeth) at the ends, which are aligned under normal conditions. The clamping of the coupling halves to each other is ensured by a spring. The principle of operation of a spring-claw coupling is based on the slipping of the coupling halves relative to each other in the event that the moment of resistance begins to exceed the pressing force of the spring. At the same time, a characteristic cracking sound is heard, signaling that the nozzle is jammed.

It is believed that a spring-cam clutch is more reliable than a friction clutch, however, it also has a serious drawback. It consists in the fact that the tips of the teeth are rolled, which leads to the coupling being activated even in the case when the nozzle is not jammed, but only a lot of resistance has arisen. Some craftsmen cope with this problem by placing a 3-5 mm thick washer under the spring, which increases the compression force of the spring and, consequently, the moment of actuation of the clutch. However, excessive rigidity of the coupling is also undesirable, since it makes the tool jerk too much when the attachment jams, which can lead to injury to the hands of people working with the hammer drill.

How to work with a hammer drill correctly?

If before the hammer drill you had an impact drill or no power tools at all, then don’t rush to drill and chisel, first learn how to use a hammer drill. The instructions indicate the operating mode for which the tool is designed, in other words, how many minutes to work and how long to rest for an hour. Without following the regime, we will get overheating. This can have disastrous consequences for an electrical product. It should be remembered that higher-power hammer drills with a low load (drilling holes) can work longer without interruption and vice versa.

The drilling mode for our tool is gentle; you can work in it almost without interruptions. Impact drilling and chiselling mode are the most difficult for the tool. If a lot of construction dust is generated during work, then you need to pause until the dust settles. Grains of concrete and stone, falling into the chamber between the piston and the ram, act as an abrasive material, destroying the cylinder walls. This leads to a decrease in the impact force of the hammer drill, rapid wear of the commutator brushes and gears of the gearbox.

When choosing a tool, do not chase power and impact force; adequately assess the upcoming work, looking ahead 3-8 years in advance. A correctly chosen hammer drill will serve faithfully for many years. By observing operating modes and cleaning the tool after each use, you will not have to study the inside of the hammer drill or contact service.

- Author: Manager Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

The difference between a rotary hammer and an impact drill

To choose a suitable power tool, you need to consider the classification, design and operating principle of rotary hammers. This equipment has a number of characteristic features. Do not confuse a rotary hammer with an impact drill, since the principle of their operation is completely different. The blows in these instruments have different strengths, since their origin is different in both types of power tools.

In an impact drill, the punch operates through a gear drive that has two wheels (ratchets). The productivity is quite low, the impacts are relatively weak. Hard concrete will not yield to an electric drill with an impact mechanism.

Considering the operating principle of the Kalibr, Bosch, Interskol and other manufacturers, the following can be noted. This tool is designed for drilling holes in hard materials. The hammer drill system can be electro-pneumatic or electro-mechanical. This allows you to create a high-power impact force. The master will not need to put pressure on the tool. The easiest way to work is with pneumatic hammer drills. This is a modern mechanism that is popular today.

The principle of operation of a complex system

Considering the principle of operation of a rotary hammer, it is worth noting the operation of a more complex mechanism. Some models use more complex electronic systems. They are called constant electronics. Such a system is designed to maintain a constant, specified energy upon impact.

This system avoids performance degradation if the load increases. This is especially noticeable at low speeds.

Some professional models have an armature rotation control function. If the load increases, reserve power is activated.

Often the master has to drill holes in materials that create a large amount of dust. This leads to rapid wear of the tool barrel and also negatively affects the health of the master. Therefore, many models of modern rotary hammers are equipped with a built-in vacuum cleaner. It collects small abrasive particles from the drilling area, increasing comfort and quality of work.

Main types of rotary hammers

Rotary hammers are divided into types according to two main criteria.

Classification by engine power, impact force and weight

Rotary hammers come in household (light), semi-professional (medium) and professional (heavy) types.

- Models of the first type are most often used for drilling holes for dowels and anchors at home. Household hammer drills include tools weighing up to 3–4 kg. Power varies from 400 to 800 W. The maximum impact force for light tools is 3 J.

- Models of the second group weigh from 5 to 8 kg. Power reaches 1500 W. Impact force - up to 8 J. Semi-professional tools penetrate reinforced structures well.

- Rotary hammers of the third type are best suited for performing operations such as chipping and destroying surfaces under conditions of high intensity and large volumes of work. Power reaches 2000 W. The impact force exceeds 10 J. The weight and dimensions of the tools also increase. Heavy duty hammer drills are designed to drill large holes in materials with maximum hardness.

Classification by food type

According to this criterion, rotary hammers are divided into 3 types.

- Network. Connect to the network (220 and 380 V) via wires. They are used most often.

- Rechargeable. They are powered by batteries, which can be built-in or external. They do not function for long without recharging, but are indispensable in the absence of opportunities to connect to electrical networks at work sites.

- Gasoline. Rotary hammers of this type can also work autonomously. They are equipped with gasoline engines. Fuel is poured into small tanks. Such hammer drills are most often used for road work.

Photo No. 6: powerful gasoline hammer drill