A hammer drill is a tool used to perform a variety of construction work. The item has earned popularity due to its power and great functionality. However, it is worth remembering that the hammer drill operates under constant load, so some parts may fail. Before removing the chuck from the hammer drill, it is recommended to study all the features of the process.

The design of rotary hammers of different brands differs

How does a hammer drill chuck work?

Almost every tool is versatile. There are many unique heads, attachments and adapters for rotary hammers on sale, but the chuck is considered the most important for the main work.

Experts recommend always having an additional part in stock. In addition, it is believed that for each type of activity it is worth selecting a specific cartridge.

The main types are:

- Quick-clamping. It is better to choose for work when a quick change of attachments is required.

- Key. A good option for large diameter drills.

Before disassembling the hammer drill chuck, it is recommended to consider its design. In older versions, the drills were connected using special cams. Modern models use fixation using guide wedges and locking balls. Additional elements may also be present:

- speed controller,

- electronic and brush reverse,

- quick change system,

- various indicators,

- friction clutch,

- anti-vibration system,

- immobilizer and others.

Important! The complete set mainly depends on the hammer drill model. Models from well-known manufacturers are equipped better.

There are several types of cartridges

Rules for using the device

Rotary hammers are widely used in modern construction industry; they have replaced monotonous and ineffective manual labor. But its use is associated with certain risks that you need to be aware of before starting work.

First of all, you need to work with a working tool in the normal mode permitted by the manufacturer. The power supply must be provided through a cable whose cross-section corresponds to the power consumption.

After transporting the hammer drill in the cold season, you must wait at least half an hour to soften the lubricating fluids inside the mechanism.

The operator performing the work must be healthy. Before work, you must study the instructions for the device and safety regulations.

Removing the working tool

To remove a drill or attachment after work or for replacement, you must:

- Wait until the rotation of the chuck has completely stopped.

- Pull the base of the chuck down as far as it will go.

- Remove the drill from the chuck.

- Release the chuck base.

Attention! The drill becomes very hot due to friction. Use gloves to avoid getting burned.

Additional tool features

In addition to the above, the standard set of options in a modern hammer drill includes:

- ruler for determining the depth of the hole;

- lever for fixing the working position of the start button;

- safety clutch - stops the motor when the drill jams.

And also the design of each device includes the following systems:

- dust removal - an impeller on the engine with a system of dust removal channels;

- vibration damping - special springs between the body and the power unit;

- electronic regulation of operation and control of the condition of brushes on the electric motor commutator.

An important rule, failure to comply with which can lead to failure of the hammer drill. Switching modes should only be done when the tool is completely stopped.

Working with wood

Twist drills are used to create holes in wood surfaces, which can also be used for working with metal. But to achieve a clean and neat recess, drills with a special attachment and recess are used. They are made from carbon or alloy steel and are designed for wood only.

- Screw. It has only one spiral and has a particularly sharp edge. This shape allows you to minimize the scattering of chips during operation of the hammer drill, allowing you to clearly see the drilling site. The edges of the treated surface are smooth along the entire length.

- Spiral. Designed to work on medium-thick surfaces, for example, to create holes for cabinet handles.

- Feather. Designed for shallow recesses (about 2 cm).

- Fostner drill. Designed for fastening type holes (for example, for hinge holders of hinged doors). A distinctive feature is the presence of a point for centering and a trimmer with a sharpened edge.

- Annular. Outwardly it looks like a crown or a glass with corners around the edges. Used for recesses with a diameter of 10 cm or more.

Concrete accessories

The drill bit sizes for concrete hammer drills may vary. This indicator depends on the diameter of the hole you need to get. But all drills for stone, brick and similar coatings have a hard tip. It is made from a special alloy, which gives it higher characteristics. Drilling of such coatings occurs through impact-rotational motion.

If conventional bits have a cylinder-shaped shank, then the drill bit for a hammer drill comes in other shapes. To drill a small hole in a concrete surface, use an auger drill with a carbide tip. Large holes are cut using a crown with carbide teeth along the edges. Diamond-coated tools are also popular due to their durability.

For granite surfaces, it is customary to use nozzles based on Pobedit. This tool has different softness and is therefore suitable for different surfaces. For ceramic tiles, an excellent solution would be a spear-shaped drill with a tungsten or pobedit tip. For glass, it is recommended to use a crown with a special coating around the edges.

READ How to drill through a concrete wall of a house

How to attach a drill bit to a hammer drill? change cartridge

Wood attachment

To make small holes in wooden coverings, you can use the simplest twist drill, which is also suitable for metal. But recesses that require higher precision must be drilled with special attachments. They are designed to work on wood surfaces and are made from alloy or carbon tool steel. Such drills also come in several types:

- Screw. It has a sharp edge and has a single spiral. The convenient shape ensures maximum removal of excess chips during operation of the hammer drill. It is perfect if you need to create a hole with smooth edges and at great depth.

- Spiral. Suitable for producing medium and small holes. In some cases, it can be replaced with an analogue for metal, but the result in this case will be of poor quality.

- Feather. It is used to create recesses with a diameter of 1 to 2.5 centimeters.

- To drill a blind hole with clear dimensions, the best option is a Forsner drill. Its characteristic feature is a trimmer with a sharpened edge and a point for centering. Ideal for working with soft wood species.

- An annular drill, which is made in the form of a crown with jagged edges. It is used when the diameter of the required hole reaches 10 centimeters. The kit includes several attachments.

What types of chucks for rotary hammers are there?

There are different types of hammer drill chucks, each option has some differences.

- SDS. A part of this type appeared relatively recently, but is considered the most optimal option for tools of this type. It is supplied with five types of clamping devices - regular, top, quick, plus, max.

- Gear-crown key. Classic version of the cartridge. To use, you will need a special key to help fix the working attachment. With its help, the fastening mechanism is compressed and unclenched. Considered very reliable.

- Quick-clamping. They are easy to use. You just need to clamp the mechanism of the product and you can start working.

- Clamping with one coupling. Such cartridges are installed only on rotary hammer models that have automatic blocking of the working shaft. As a result, the shank of the nozzle is clamped using manual rotation of a special sleeve.

- Transitional. A rotary hammer is often used with different attachments, so special adapters are needed. Thanks to such elements, the tool can be used in various fields.

The procedure is carried out with special care so as not to lose details

How to remove a chuck from a hammer drill

Before removing the attachment from the hammer drill, you need to accurately determine its type. After this, the tool is disassembled and elements begin to be changed.

Attention! It is best to carry out the procedure on a table so as not to lose important details.

During disassembly, the elements are laid out in the order in which they were removed - then it will be easier to assemble the instrument.

The process includes several stages:

- Remove the rubber tip from the end.

- Use a screwdriver to remove the first retaining ring.

- Pull the plastic clutch cover down.

- Remove the second retaining ring.

- Remove the clutch cover.

- Remove the springs, retaining plates and balls.

The parsing process is complete. If you need to change the chuck on a Bosch, Makita, Decker or, for example, Elitech hammer drill, you will need to remove the remaining part of the bushing. A new part is installed in its place.

To understand what kind of device the hammer drill mechanism has, you need to inspect the tail part of the nozzle. It has several recessed areas called grooves. The nozzle that will be installed in SDS-plus cartridges is distinguished by the presence of 4 notches - 2 closed and 2 open.

What is SDS

SDS (SDS) is an acronym made up of the first letters of the words Steck, Dreh, Sitzt, which translated from German mean “insert, turn, secured.” It is on this simple, but at the same time ingenious principle that the SDS cartridge, developed by Bosch engineers in the 80s of the last century, works. Today, 90% of all manufactured rotary hammers are equipped with these easy-to-use devices, which ensure high reliability of fixing the working tool.

SDS chucks are often called quick-release chucks, but they should not be confused with devices in which clamping is achieved by rotating the couplings. Unlike traditional quick-release chucks, the SDS clamp does not need to be rotated to secure the tool; you just need to hold it with your hand.

To understand the design of a hammer drill chuck of this type, as well as the principle of its operation, just look at the tool shank, which is designed to be fixed in such a device, or the SDS adapter. This shank has 4 grooves, two of which are open at the end of the shank, and the other two are closed. Open grooves act as guides; they ensure the correct position of the tool when it enters the chuck. The closed grooves, in turn, ensure the fixation of the shank in the hammer drill chuck.

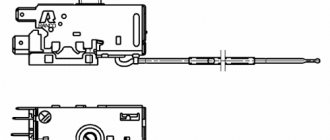

Scheme of the impact mechanism of a rotary hammer

In the inner part of the SDS cartridge there are special balls that perform two functions simultaneously. At the moment when the tool is just inserted into the hammer drill, the balls along which the guide grooves move ensure its correct position. After the tool is inserted all the way, such balls fix it, for which it is necessary to turn it a little until the balls enter the closed grooves of the shank. To make using the SDS chuck even easier, it is recommended that the tool shank not only be thoroughly cleaned after each use, but also lubricated.

It should be borne in mind that due to the design features of SDS chucks, the tool that is fixed in them is subject to slight radial runout at idle, which does not in any way affect the accuracy of the processing performed. Meanwhile, the presence of a small play between the shank and the inner surface of the chuck protects the latter from the impact to which drills are exposed during the operation of the hammer drill.

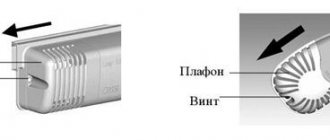

To protect against contamination, all hammer drill chucks are equipped with rubber boots.

How to disassemble a hammer drill chuck

In some cases, it becomes necessary to disassemble the cartridge itself, for example, for cleaning, lubricating or changing some parts. In order to carry out the process correctly, it is recommended to know the brand of the manufacturer, because the main process depends on this. For example, more modern brands (Dewalt, Metabo, Sturm, Caliber) are very similar in design to their foreign counterparts and are disassembled using the same schemes.

Analysis diagram based on the Bosch brand (products of this brand are the most popular):

- Unscrew the plastic part and remove the rubber seal.

- Using a screwdriver, carefully remove the ring securing the structure and the washer.

- Remove the next retaining ring.

- The SDS clamp is disassembled according to a certain scheme - first remove the ball, then the washer, and lastly the spring.

Important! It is imperative to follow the described sequence so as not to break the product or interfere with its operation.

After assembly, all fasteners must be checked

How to insert a chuck on a hammer drill

In order to insert the cartridge into the hammer drill and assemble the device, you will need to perform the following steps:

- Screw the drill onto the product (the procedure is done until it stops).

- Place the screw in the slot.

- Tighten completely using a screwdriver.

It is recommended to choose the most suitable chuck option and not skimp on parts to avoid tool breakdowns in the future. Experts recommend taking a hammer drill with you and selecting the element right away in the store.

If the nozzle gets stuck

Like any tool, even the highest quality hammer drill When performing work, this becomes a problem that has several options and reasons.

Firstly, when the drill is stuck in a removable chuck, and secondly, if the nozzle is jammed in the hammer drill itself.

When the problem is in the tool clamp itself or the removable head, then simply pour a little liquid like WD-40 into the chuck and wait a little. The composition will relax the grip of the clamping device and the drill can be removed without problems.

The cause of the malfunction can also be the poor quality of the drill itself. If a cheaper and softer metal alloy was used in manufacturing, the nozzle may be damaged by the hammer drill during operation.

There are several ways to fix this problem. The first thing you need to try is to hold the drill in a vice and, holding the tool in your hands, loosen the attachment and pull it towards you. If the deformation is not very serious, then the nozzle can be pulled out.

The second option involves double fixation with a vice - a hammer drill on one side, and a drill on the other. Then take a small hammer and hit the drill towards the exit from the clamp. For this operation, you can use WD-40.

When no other method helps, you can try removing the chuck parts and turning the drill in the opposite direction about 90 degrees. However, this technique can completely damage the parts of the clamping device.

But if this option does not work, it is better not to try to disassemble the device. such a hammer drill to a workshop of competent specialists.

It should be noted that in order to reduce the possibility of such breakdowns to a minimum, it is better to choose high-quality attachments from leading brands. As a rule, such investments are recouped by the long operating time of the tool.

The nozzle can get stuck not only in the mechanism of the unit, but also in the wall during operation. In this case, you can try to free the drill or drill by turning on the reverse motion on the device.

READ How to lubricate the inside of a hammer drill

If this method does not work, then the nozzle is released from the clamp, another one is inserted, and after drilling out the wall around the stuck tip, it is removed. If the drill breaks during work, then its remains are removed from the clamp, and the piece stuck in the wall is drilled out or simply cut with a grinder flush with the working surface.

Detailed instructions for attaching a drill to a hammer drill are in the video below.

Reverse

The reverse function allows you to switch the direction of rotation of the chuck in different directions.

Often, when drilling reinforced concrete structures, the drill rests on the reinforcement and enters into a clinch with it. In order to release it, a reverse switch is provided, which makes it possible to turn the drill in the opposite direction and continue drilling, bypassing the fittings. Usually the reverse button is located directly next to the start button of the unit.

The reverse mode turns the hammer drill into a screwdriver, which can be used to tighten and unscrew bolts, nuts and screws of any size and configuration.

Features of chuck removal and repair for different hammer drill manufacturers

Different hammer drill models have a specific design, so the process for changing the chuck is different. There are some peculiarities, but basically all elements are removed in the same way.

- Makita. Disassembly is carried out similarly to Bosch rotary hammers. In order for the device to last longer, it is recommended to allow the device to cool down during operation, as well as to carry out regular maintenance of the item.

- Bison A popular brand, similar in design to its foreign counterparts.

- Interskol. As with any other model, the main requirement in the procedure is care and consistency.

- Bosch. Disassembly and assembly is carried out according to the schemes described above.

- IE4729e. Drills were previously produced under similar numbers. In most cases, the cartridges on them were with conical nozzles (Morse taper 12), so the disassembly sequence is carried out using technology suitable specifically for this type.

Depending on the model, the process may differ.

Removing the cartridge from the hammer drill is quite simple. Almost all models can be disassembled in the same way, and all you need is a high-quality screwdriver to work. If you plan to replace the part with a new one, then it is better to go to the store with the device to choose the most suitable option, otherwise you may damage the tool. It is recommended to remember that on devices manufactured a long time ago, the pattern for removing the cartridge may differ, so if you are not confident in doing the repair yourself, it is better to seek help from a specialist.